Water Quality Insert Filters Seal the Deal

Fabco Industries is pleased to announce a renewal of a 5-year Blanket Purchase Order agreement with the County of Nassau to furnish and install its’ water quality insert filters within the county. This marks the 2nd consecutive agreement Fabco has been awarded for these products and services.

The Blanket Purchase Order provides a fixed price, covering the water quality insert filters, installation, and maintenance activities, giving Nassau County the confidence to specify various filter types while staying within budgetary estimates. During the term of the previous blanket order, Nassau County was able to complete a number of stormwater quality insert filters improvement Nassau County Seal projects utilizing plans and funding from their older 2004 and 2006 Environmental bond acts. Fabco water quality filters were used in multiple capital improvement projects throughout the county where a decentralized approach and repurposing of existing storm drain infrastructure was determined to be a cost effective and sustainable solution. Currently over 3,000 units have been installed under this program alone.

Post construction installation and performance reports have demonstrated pollutant removal effectiveness for sediments, trash/debris, nutrients, hydrocarbons, heavy metals and bacteria in targeted watersheds.

Municipal users have found the inlet filters and screening technologies to be quick to implement, cost effective, adaptable to the cold climates and easier to maintain than expected.

The following design example provides guidance for the implementation of manufactured water quality inlets and catch basin inserts for purposes of runoff quality management on VDOT facilities projects. Catch basins are chambers or sumps which provide the entrance point for surface runoff into a stormwater conveyance system.

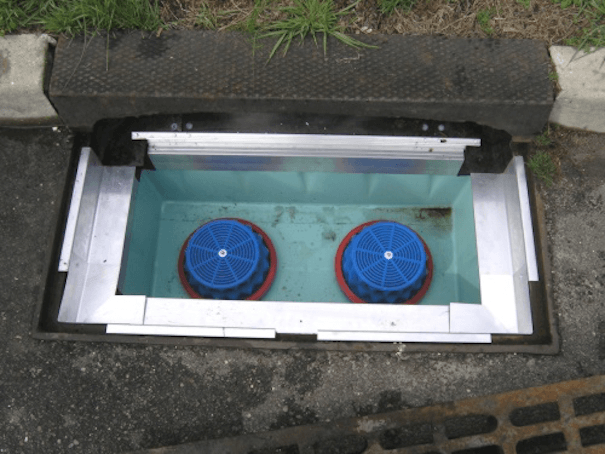

Catch basin inserts are employed to intercept coarse sediments, oils, grease, litter, and debris from the runoff prior to its entrance into the storm sewer. Catch basin inserts are well suited to parking lots, maintenance yards, and other locations where runoff travels directly from an impervious surface into the stormwater conveyance system. (VTRC, 2004)

Water quality inlets encompass a broad spectrum of BMPs designed to remove non point source pollutants from runoff. These structural BMPs vary in size and treatment capacity, but typically employ some form of settling and filtration to remove particulate pollutants. Water quality inlets may exist as hydrodynamic separator systems (see Design Example 15), multi-chambered treatment trains, and a wide array of proprietary products discussed later in this design example.

Many types of catch basin inserts/water quality inlets exist; however, these different configurations generally exhibit similar strengths and shortcomings. The following presents the most common variations of water quality inlet filtering systems.

15.1.1 Tray Type Tray type filters function by passing stormwater through a filter media situated in a tray located around the perimeter of the inlet. Runoff enters the tray and exits via weir flow under design conditions. Runoff from large storms simply passes over the tray into the inlet unobstructed.

Bag type inserts are made of fabric and placed in the drain inlet around the perimeter of the grate. Runoff entering the drain must pass through the bag prior to exiting through the drain pipe outlet. The system is usually equipped with overflow holes to prevent backwater conditions during heavy runoff producing events.

Basket type inserts set into the inlet and can be removed for periodic maintenance. Small orifices permit small storm events to weep through, while larger storms overflow the basket. Basket type inserts are useful for filtering trash, debris, and large sediment, but require consistent maintenance.

Inlets can be designed such that space is created below the invert of the outlet pipe(s) for sediment and debris to deposit. Generally, this space will be 6 to 12 inches deep. Small weep holes should be drilled into the bottom of the inlet to prevent standing water for long periods of time. Note that if weep holes are used to drain a sumped inlet, the inlet must conform to applicable design requirements for infiltration facilities. Inlets equipped with a sump require regular maintenance and sediment removal.