Fabco Industries Stormwater Phosphorus Treatment Guide

A Comprehensive Stormwater Phosphorus Treatment Guide for Phosphates and Nitrogen Compounds

Our Stormwater Phosphorus Treatment Guide makes it easy to understand what phosphorous is, how it affects stormwater, and how we create solutions to treat the problem at the source.

What Is Phosphorous?

Phosphorous, a natural element found in rocks, soils, and organic matter, is a nutrient required by all organisms for normal life processes. Pure phosphorous by itself is unusual and more typically combines with oxygen to form phosphate molecules (PO -3). Phosphates when combined with carbon-based molecules are organic and typically bound to organic materials such as sewage, food residues or even organic pesticides. Phosphates not associated with organic material are inorganic.

While animals can utilize both types, plants can only use inorganic phosphates. In nature due to the relative scarcity of inorganic phosphate it is termed a “Growth Limiter” because it occurs in the least amount relative to the plants total nutrient requirements.

Both organic and inorganic phosphates can be dissolved in water or attached to fine particles in the water column. Free inorganic phosphates dissolved in the water can be used directly by plants. These, soluble, free inorganic phosphates are called orthophosphates or “Reactive Phosphate*” (soluble reactive phosphorous). For maximum effectiveness, commercial fertilizers are manufactured to provide high levels of soluble, orthophosphates to support robust plant growth.

During rain events uncontrolled runoff flowing from fertilized lands can contain high levels of dissolved inorganic phosphates. If this supercharged runoff enters a natural body of water, it can easily upset the natural balance resulting in massive algae blooms. The State Environmental Resource center (www.serconline.org) suggests that one pound of phosphorous can result in the growth of 350 – 700 pounds of green algae.

*Soluble reactive phosphorus also known as SRP is a dissolved form of phosphorus. Because dissolved phosphorus is readily available for uptake by plants, the amount of SRP found in a lake provides a good estimation of how much phosphorus is available for algae and plant growth. Because aquatic plant growth is typically limited by phosphorus, added phosphorus especially in the dissolved, bio-available form can fuel plant growth and cause algae blooms. Sources of SRP can include: failing septic systems, animal waste, fertilizers, decaying plants and animals, and re-suspension from the lake bottom. Because phosphorus is cycled so rapidly through biota, SRP concentrations as low as 0.005 mg/l are enough to maintain eutrophic or highly productive conditions in lake systems.

How Can We Treat Phosphorous?

As a leading supplier of storm water filtration systems and filter media solutions, Fabco Industries recognized that while it is possible to retain the fine particles associated with phosphates a new treatment method was needed to treat the important soluble orthophosphates.

After researching and bench scale testing several available technologies Fabco began working with a ferrous-based compound with a known affinity to phosphates. During the development phase, Fabco Engineers and Chemists worked closely with a Marine Biologist and Polymer

Chemist to create an environmentally safe product that bonds this advanced treatment technology to an advanced synthetic base material. The result of the collaboration is Fabco’s FabPhos filtration media.

The unique synthetic base material is a fibrous mat that provides enormous surface area similar to fine Ion-exchange resins while resisting blinding and the release of “fines” during operation. When packaged into one of our unique cartridge filters and installed into a Fabco stormwater unit, the combined treatment methods of mechanical filtration (for fine particles) and FabPhos has proven to be capable of reducing phosphorous levels by up to 80%

FabPhos Benefits

- Proven effectiveness under rigorous field conditions.

- Proprietary filter media provides enormous surface area without using small particles, which can severely restrict flow, bind easily and can release fine particulates.

- Ability to bind large quantities of phosphate permanantly to its surface without negatively influencing pH or other water quality factors.

- Non-hazardous and non-biodegradable.

FabPhos Performance on Nitrogen Compounds

During field studies of the FABPHOS technology, installation sites were selected in proximity to well-maintained landscaped areas. While phosphate effectiveness was the primary focus of testing, elevated levels of nitrogen compounds were also expected in the surface runoff that would be directed to the filters.

Prior to these field trials initial small-scale testing had shown that FABPHOS was effective on both phosphates and nitrogen compounds. However, there was some uncertainty on how well this effectiveness would transfer to the real world.

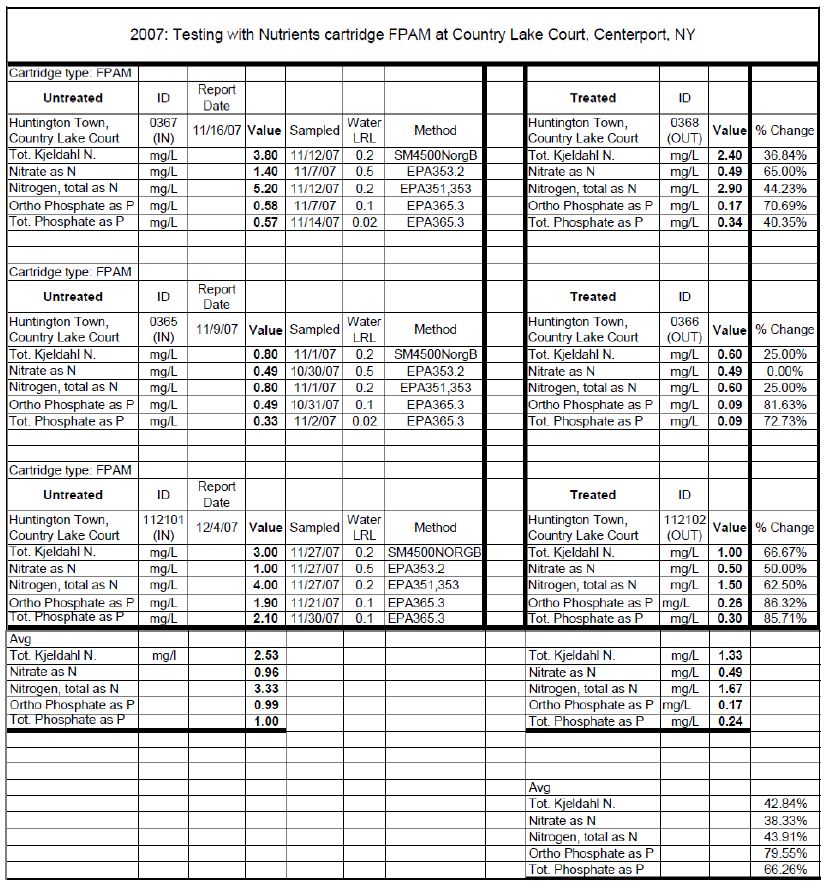

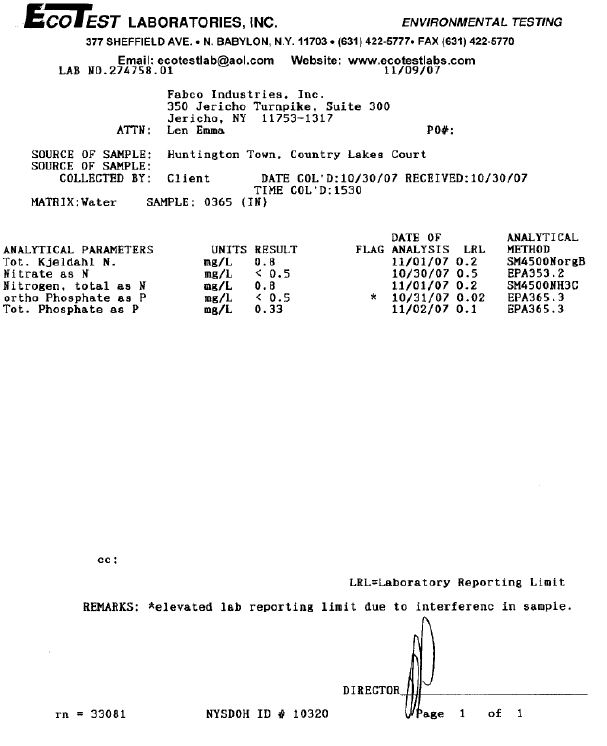

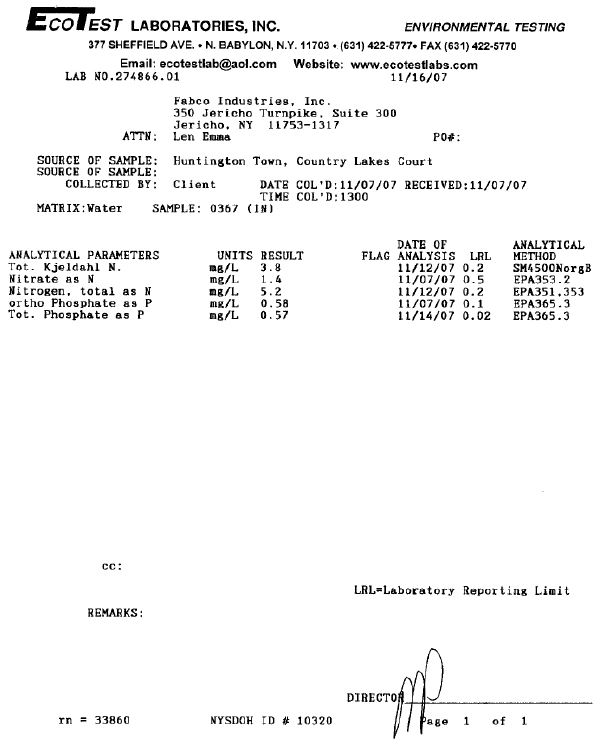

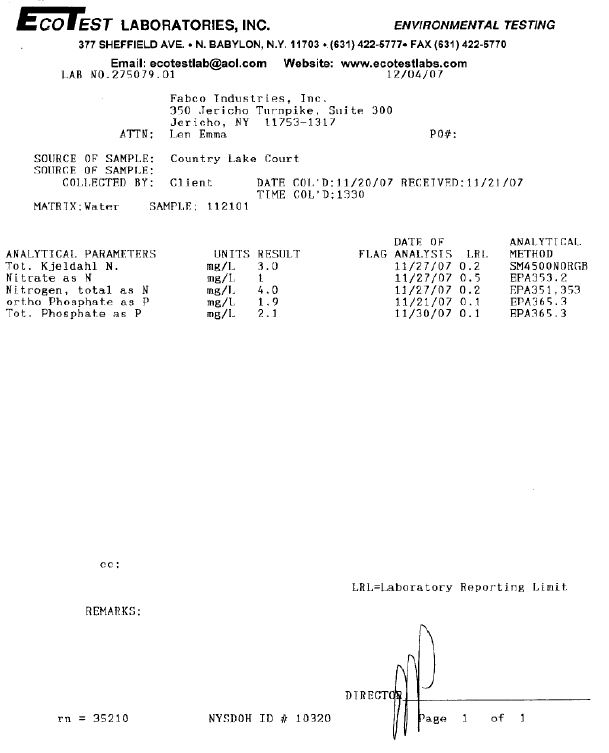

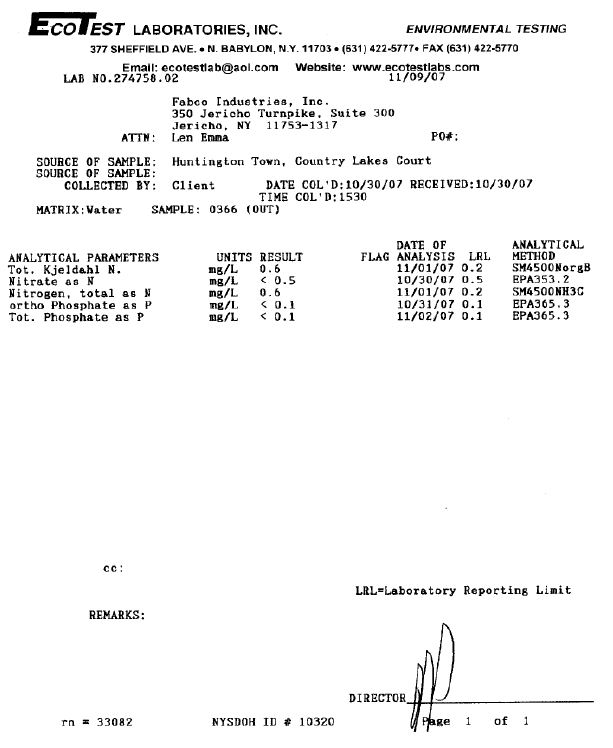

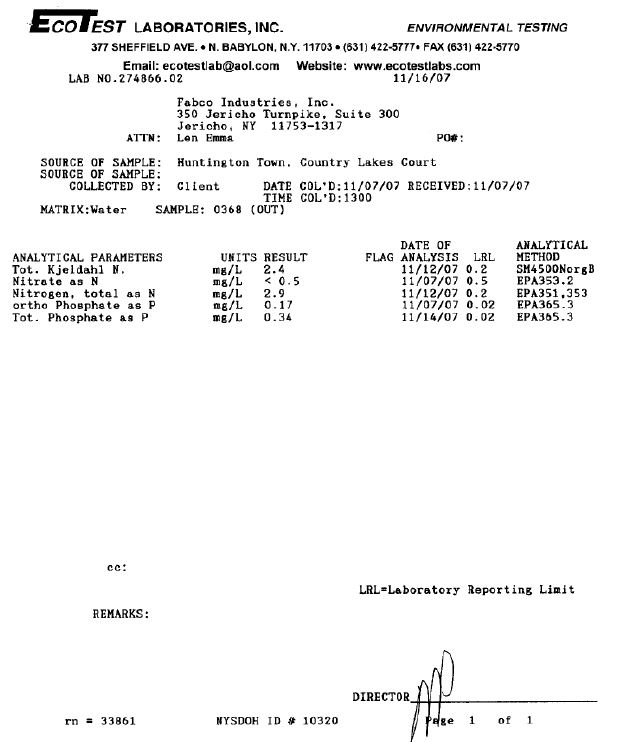

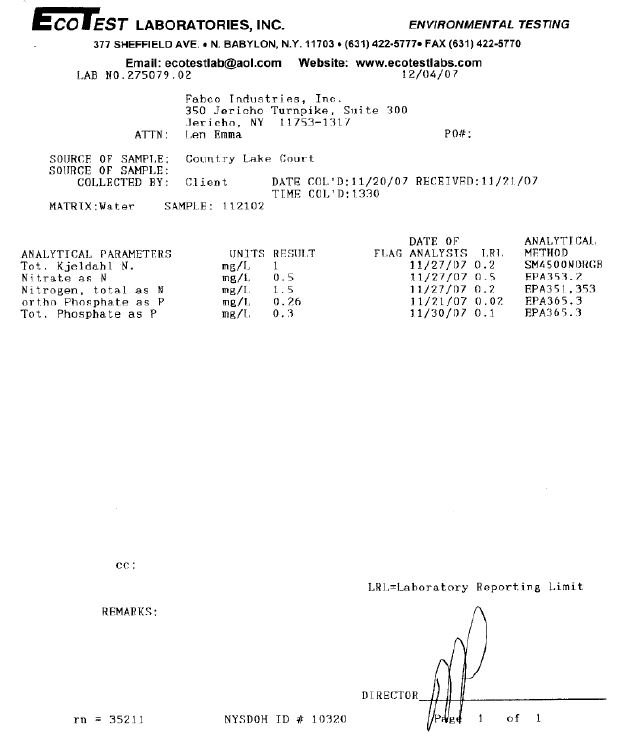

During sample testing 5 parameters were identified for analysis: Total and Ortho phosphates, Total Kjeldahl Nitrogen, Nitrate as N and Nitrogen, total as N.

The analysis of samples taken during multiple storm events showed an average 64% reduction in Phosphates and a greater than 30% decrease in the 3 measured nitrogen compounds.

FabPhos Summary

FabPhos is a proprietary filtering media that can significantly reduce the concentration of both soluble, orthophosphates and nitrogen compounds in storm water runoff. FabPhos is safe for the environment, has a high capacity for nutrient treatment and it does not leach captured pollutants at saturation. When combined with an effective TSS treatment device such as an underground hydraulic separator or Fabco’s StormBasin insert filter FabPhos can help stormwater managers meet the greater than 40% reductions required by many states for phosphates as well as nitrogen

compounds.

FabPhos Field Test Results

FabPhos Field Test Results

a) Fabco Industries StormBasin Protects NYC Drinking Water Supply by Reducing Phosphorous

This project involved the collaboration of multiple parties over the course of the last decade, including the East of Hudson Watershed Corporation, a local development corporation established by the municipalities in Northern Westchester, Putnam, and Dutchess Counties in New York City Watershed. Its aim is to install stormwater retrofit projects to meet the requirements for phosphorous reduction as defined by the New York State Department of Environmental Conservation (NYSDEC). The corporation works in conjunction with the NYSDEC and the New York City Department of Environmental Protection (NYCDEP) to further Stormwater MS4 quality projects in the Croton and Kensico Reservoir Basins. Brewster Heights, the project site, is a small community in the Town of Southeast in southern Putnam County, NY.

Fabco Industries is a NYS based manufacturer of quality stormwater treatment devices with over 5,000 installations in NYS alone.

One of the last design iterations prior to approval from the NYCDEP involved identifying an appropriate water quality Best Management Practice (BMP).

A centralized downstream approach including the installation of two hydrodynamic separators was initially considered but those units would have required realignment of mulitple existing utilities and taken up a significant footprint within the right-of-way.

The StormBasin offered a significant reduction of pollutant load removal costs while also providing decentralized implementation that takes advantage of the existing catch basins. Fabco Industries StormBasin solution is a cartridge driven decentralized approach to stormwater runoff water quality treatment.

Fabco has numerous cartridges that can be targeted at specific pollutants. The NYSDEC and NYCDEP have approved the Fabco Nutrient Cartridge with both FabGuard AND FabPhos proprietary medias to provide 50% phophorous removal at its peak treatment flow rate of 0.25 ds per cartridge (05.0 ds per double cartridge StormBasin catch basin).

The FabGuard media’s open cell foam acts as a mechanical pre-filter for the cartridge by retaining sediment, trash and debris while its unique anti-microbial technology prevents the formation fo bacteria within the media itself.

The proprietary FabPhos filtering media treats soluble orthophosphates in stormwater runoff.

Steven Lauria, PE and Principal of Woodard & Curran, stated:

“The first five years of retrofits revealed that for the program to be successful moving forward, there needed to be cost- effective and low maintenance retrofit solutions that did not require the modification of existing infrastructure or land disturbance. One of the greatest challenges of implementing retrofits on public and private property is limiting the impact to existing infrastructure, property, and current operations. The Storm Basin solution met all the challenges of the retrofit model as a cost-effective and low maintenance solution. StormBasin has the potential to save the EOHWC millions of dollars when compared to other NYSDEC approved retrofit practices.”

Treating a fraction of the drainage area, the StormBasin inserts were able to obtain a reduction of 7.43 kg/y – and at less than one third the installed cost of the HOS solution. Most impressive was Fabco’s StormBasin solution did so with no required realignment of existing utilities!

The decentralized nature of the StormBasin solution being both “at grade” and “at source” has several advantages over a buried downstream device. StormBasin installations are easily inspected and maintained at grade and once installed can protect the downstream infrastructure.

Kevin Fitzpatrick, Director of Engineering for the EOHWC, mentioned “Fabco Industries and Bill Stoecker were attentive and responsive throughout the entire project to ensure we had the best solution in place to fit the Corporation needs.”

14 Fabco StormBasin units with a total of 29 cartridge filters were installed by Fabco’s Team over a two-day period in November 2018. Several different styles of units were utilized to accommodate the various catch basins, frames and grates that exist in the community.

The long-term success of these installations relies on the timely approach to maintenance of the drainage area and the catch basins themselves. To this end, StormBasin units have been designed to make biannual cleaning and annual replacement of the cartridge easily done by any local workforce. Looking to the future, StormBasin is to be implemented in several EOHWC projects. This solution should be considered in any situation where water quality improvement is needed, economics is a driver, and ease of inspection and maintenance is desired.

b) Fabco Industries Insert Filters Used to Retrofit MS4 System in Phosphorous Limited Lake Watershed

The Challenge:

Lake Oscawana in Putnam Valley, NY was listed as phosphorus impaired by the New York State Department of Environmental Conservation (NYS DEC) in 2004 and subsequently a Total Maximum Daily Load (TMDL) was issued. The TMDL was a result of the diligent effort of many researchers and scheintific professionals who collected and analyzed lake water quality monitoring data going back to circa 1987. The TMDL was finalized and documented in the 2008 Management Plan prepared by Princeton Hydro, LLC. Stormwater from developed land was identified as a major

contributor to the extrenal phosphorous load.

The Solution:

The Management Plan identified several strategies, which were then prioritized for implementation based on cost, impact on watershed and operation and maintenance requirements. One of the strategies selected for implementation was the retrofit of municipally owned catch basins that discharge stormwater runoff to Lake Oscawana. As a result, the Town of Putnam Valley and Town Engineer (J Robert Folchetti Associates) competitively bid the retrofit of approximately 100 stormdrains in June 2011 and awarded the bid to Fabco Industries. The project was completed

following a two week installation period in mid-October.

Specifications targeted two levels of treatment based on location of the drain and physical limitations of the existing infrastructure. The insert devices were required to treat a frequently occurring runoff event and have adequate hydraulic capacity to safely pass a peak runoff event.

Level one specified a geotextile sack device capable of removing gross particulates, oils, grease and phosphorous loads associated with organic debris, and gross particulates. Level two specified a cartridge type filter capable of removing fine particulates, hydrocarbons and nutrients (dissolved and particulate bound phosphorous).

c) Protecting the Source – Palm Bay, FL and Brewster Heights

stormh20.com – By Carol Brzozowski

Whether they’re in place to protect a drinking water supply or aquatic life, drainage and filtration systems act to keep pollutants and debris out of the storm sewer system. Increasing development and the associated creation of impermeable surfaces call for solutions that are cost-effective while offering an optimal level of performance.

Palm Bay, FL

The 156-mile Indian River Lagoon plays a large role in Palm Bay, FL’s economic and residential growth, and it needs to be protected from future stormwater pollution as the area redevelops.

Palm Bay is experiencing an influx of jobs driven by major tech employers located within and surrounding the city, including Harris/L3, the Florida Institute of Technology, Northrup Grumman, and Raytheon among others.

Opportunities for a highly skilled, young, technical work force to live in the city have been hampered by the lack of a downtown district or new rental apartments. Palm Bay formed a business improvement district, establishing the Bayfront Community Redevelopment Agency in an effort to retain tech workers in town by helping private developers to create a downtown district.

Northshore Development is developing a mixed-use project, anchored by a 320-unit apartment complex near the Indian River Lagoon.

The lagoon has experienced years of heavy nutrient pollution and land disruption issues, spawning algae blooms, fish kills, and habitat loss. To stem the decline, the City of Palm Bay, the St. Johns River Water Management District, the Florida Department of Environmental Protection, and the counties of Brevard, Volusia, Martin, and Indian River banded together to create the Indian River Lagoon national Estuary Program Council. Its aim is to use strategic projects to reduce 900,000 pounds of combined nitrogen and phosphorous loads by 2028.

While many stormwater pollution reduction projects have been funded entirely by the municipalities and other public sector entities, an increasing number of private ventures are helping eliminate large portions of nonpoint-source pollution entering the lagoon.

Northshore’s mixed-use project is one such venture. There were stormwater mitigation challenges in constructing the apartment complex.

“This is a very difficult property to get the drainage and stormwater right on, because next to it is an old mobile home park from the 1970s that was built a little lower than it should have been,” says James Shonkwiler, chief development officer and COO for the Northshore Development Group.

With new drainage and storage regulations, in effort to match post-development flow to that of pre-development, the project called for the use of 3 feet of fill above what the neighboring property owner in the same watershed to the south of the site had used, Shonkwiler says, adding that a highway and railroad north of the site posed another concern regarding water flow.

“We wanted to make sure we didn’t flood this trailer park,” says Shonkwiler. “The soils were not really good. The site served as a storage area and was flooding and pushed back up. When we built the project there, we had to meet the current stormwater regulations of four inches of treatment and find a way to avoid flooding the mobile home park in any event at all, so we went all the way to the 100-year storm event.”

That necessitated building bigger ponds, which take up 22% of the site, says Shonkwiler.

“We have a lot of storage on site,” he says. “That leads us to stormwater streatment. The way you treat stormwater in Florida typically is to build a dry retention pond or elevate your existing ponds even more so it could percolate down through the soils.”

He adds, “We didn;t have good soils in the substrate for drainage. We put new soils in. We would have had to bring in another one or two feet, which made it even more difficult to avoid flooding the low-lying areas to the south of the trailer park.”

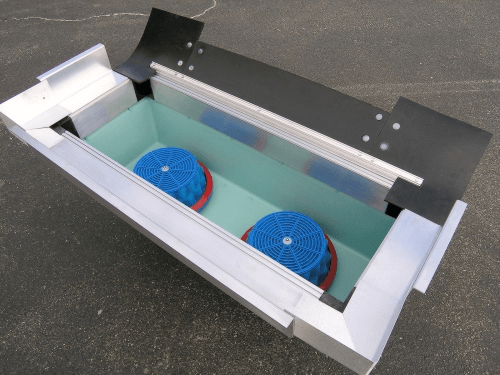

The alternative was to use two Nutrient Removing Filtration System (NRFS) vaults with integrated biosorption media to manage and treat runoff from the site, protecting the lagoon from nutrient pollution and keeping it as an attractive local ecosystem.

The NRFS is an engineered vault treatment system for the reduction of nutrients and sediment within stormwater runoff. Designed and manufactured by Suntree Technologies, an Oldcastle Infrastructure company, the Northshore Development’s NRFS vaults utilize Bold & Gold biosorption activated media along with an orifice flow control to maximize detention time to remove large amounts of total suspended solids (TSS), phosphorous, nitrogen, metals, and hydrocarbons.

Bold & Gold is designed to form sorbent surface bonds with water molecules to efficiently establish a media nutrient cycle that captures nutrients via biological consumption, resulting in the denitrification of runoff, ensuring its purity upon discharge and preventing the possibility of algae blooms in the lagoon.

Installation of the two NRFS vaults took place on March 28th in a single day as crews battled wind gusts, rain delays, and blown tires on one of the eight wide-load trucks delivering sections of the precast vaults.

The installations were accomplished through teamwork led by site contractor South Florida Gracing Inc., and including Northshore Development, the city of Palm Bay, Ferguson Waterworks, Oldcastle Infrastructure, Suntree Technologies, and the general contractor, Roger B. Kennedy.

“It kept us from adding more fill to the site and saved us in terms of retaining walls,” says Shonkwiler of the installations.

Brewster Heights, NY

A project to reduce phosphorous in New York City’s drinking water supply has entailed a collaborative effort of several parties over the past decade, including the East of Hudson Watershed Corporation (EOHWC), a local development corpration established by the municipalities in Northern Westchester, Putnam, and Dutchess counties in the New York City watershed.

The Goal of the corporation is to install stormwater retrofit projects to meet phosphorous reduction requirements defined by the New York State department of Environmental Conservation (NYSDEC).

The corporation works in conjunction with the NYSDEC and New York City Department of Environmental Protection (NYCDEP) to further stormwater quality projects in the Croton and Kensico Reservoir basins.

A recent project site, Brewster Heights, occupies approximately a half a square mile in the town of Southeast in southern Putnam County, NY.

The initial goal of the project was the stabilization of four heavily eroded channels that discharged runoff froma Brewster Heights subdivision. The channels had caused severe washout and sediment deposition onto private property and into teh new York City water supply Middle Branch Reservoir. The team sought to identify an appropriate water-quality best management practice (BMP) to address the problem.

One consideration was the installation of two hydrodynamic separators (HDS), individually located at the outfalls of the two channels where runoff was to be rerouted. The unit’ location would have required realignment of mulitple existing utilities and occupied a significant footprint within the right of way.

The existing phosphorous load of the drainage area tributary to the stabilized channels was calculated as 22.46 kilograms per year (kg/yr). The reduction credit attainable through installation of the two HDS units would have been 2.25 kg/yr. The estimated installed cost was between $80,000 and $100,000, not including the realignment of existing utilities.

The ultimate decision was to use Fabco Industries’ StormBasin instead. This BMP had been approved by NYSDEC and provides 50% phosphorous removal at its peak treatment flow rate. It can be retrofitted into existing catch basins. The StormBasin is designed to capture and retain stormwater catch basin pollutants including sediment, trash, vegetation, nutrients, coliform bacteria, oil, grease, and dissolved metals such as lead, copper, cadmium, and chromium. Cartridges are available in various configurations to target specific pollutants. The sediment and debris catch basin is designed to provide more than 8 cubic feet of storage volume in 30 by 48 inch size. The catch basin design features a hooded bypass to reduce the potential for flooding during peak storm events while still retaining sediment and debris. The StormBasin also keeps the captured material dry, simplifying maintenance and reducing disposal costs.

NYSDEC’s approval was based on a comprehensive technical submittal prepared by the engineering and science consulting firm Woodard & Curran as part of the overall East of Hudson Coalition Stormwater Retrofit Plan. Woodard & Curran had collaborated with NYSDEC to consider approving additional stormwater retrofit treatment practices into the overall NYC water supply phosphorous reduction program, allowing municipalities within the East of Hudson watershed additional options to treat and reduce phophorous in stormwater runoff prior to discharging into the NYC reservoirs.

“One of the greatest challenges of implementing retrofits on public and private property is limiting the impact to existing infrastructure, property, and current operations,” notes Steven Lauria, project manager and principal with Woodard & Curran.

Fourteen Fabco StormBasin units with a total of 29 cartridge filters were installed by Fabco Industries’ team over a two-day period in November 2018. Several different styles of units were utilized to accomodate the various catch basins, frames, and grates that exist in the community.

“The StormBasin solution met all the challenges of the retrofit model as acost-effective and low maintenance solution. StormBasin has the potential to save the EOHWC millions of dollars when compared to other NYSDEC approved retrofit practices,” says Lauria.

Treating a fraction of the drainage area, the StormBasin inserts were able to obtain a reduction of 7.43 kg/yr at less than one-third the installed cost of the HDS solution and with no required realignment of existing utilities.

The engineer of record on the project was Nathan L. Jacobson & Associates. The Brennan Construction Company served as the contractor. StormBasin is expected to be implemented in several EOHWC projects to serve the needs of the ultimate driving force in stormwater quality improvement projects to protect New York City’s filtration avoidance determination and its drinking water supply.