DownSpout Filter System

Fabco’s DownSpout Filters are designed to treat particulates and soluble pollutants contained in roof runoff.

Learn more about our unique design.

DownSpout Industrial Stormwater Treatment Filter System Overview

The Fabco DownSpout Filter is an industrial stormwater treatment system designed to treat particulates and soluble pollutants contained in runoff water from roof tops. This product is perfect for industrial facilities that deal with waste treatment, metal recycling etc. Read more about the specific applications below.

DownSpout Industrial Stormwater Treatment System Applications

Heavy Metals: Stormwater can react with metal roofs, metal components or roof mounted equipment releasing soluble metals, such as zinc, copper, lead and aluminum in to the environment. Studies have shown that zinc concentrations in rooftop runoff are substantially higher than those found in rainwater. Elevated levels of zinc in soils can lead to phytotoxicity (poisoning of plant life).

Pathogens: Birds, insects, and small mammals deposit fecal matter on rooftops and in gutters, contributing bacteria and pathogens to runoff.

Hydrocarbons: Polycyclic aromatic hydrocarbons (PAHs), dust and particulate matter from vehicle exhaust and the burning of fossil fuels can collect on roof surfaces, producing elevated PAH levels in runoff.

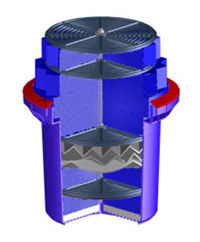

DownSpout Industrial Stormwater Treatment System Types

Fabco DownSpout Filter Systems are available in a self-contained cabinet for installation above ground, positioned next to your building or they can be integrated into commercial, high-strength plastic drainage structures for underground installation.

Above Ground DownSpout Industrial

Stormwater Treatment System

- Select filter type:

- 2 or 3 Cartridge configurationss provide filter flow rates up to 520 gpm (dependent on cartridge type). Best for sediments, solids and dissolved pollutants such as: metals, bacteria, and nutrients.

- Geotextile filter bag designs are best for high treatment flow rates when the pollutants of concern are sediment, particles or other solid materials – excellent for protection of sub-surface infiltration devices.

- Cartridge based or High Flow Geotextile filter bag system

- Large Stainless Steel filter enclosures offers multiple above ground installation and mounting options

- Hinged door panel provides easy access to filter chambers for maintenance

- 4” PVC inlet/Outlet pipes (standard)

- Built in high flow bypass

- Internal pretreatment debris screen chamber separates and keeps solid materials out of the filter cartridge area

Below Ground DownSpout Industrial

Stormwater Treatment System

- Select filter type:

- Systems for 2 or 4 cartridges provide flow rates between 520 and 1000 gpm (dependent on cartridge type). Best for sediments, solids and dissolved pollutants such as: metals, bacteria, and nutrients

- Geotextile filter bag designs are best for high treatment flow rates when the pollutants of concern are sediment, particles, or other solid materials – excellent for protection of sub-surface infiltration devices

- Perforated stainless steel Debris Basket systems capture particles and debris over 5mm in diameter. This is a more long term, robust solution that can be designed for inline filtration where there is no drop in elevation between the inlet and outlet pipes

- Cartridge based, High Flow Geotextile filter bag, or perferated stainless steel debris basket

- All of these systems are designed to fit into large, plastic sub-surface drainage structures, typically 24”, 30 or 36” diameter

- Solid manholes or grated inlets located at grade level provide access for cleaning or maintenance

- Pipe stubs incorporated into the structures move water into and out of the filter. Various pipe diameters and entrance/exit angles can be specified for the stubs.

Fabco Filter Cartridge

Our filter cartridges are designed to provide effective treatment of stormwater while maintaining high flow rates throughout the life of the cartridge. Filter cartridges are available in various configurations allowing you to fine tune performance in terms of sediments and debris, heavy metals, hydrocarbons/toxic chemicals, pathogens/bacteria and nutrients. The lightweight filter cartridge comes fully assembled and snaps securely in place with a quick twist. The modular cartridge design allows quick and easy replacement while containing the spent material for safe transport and disposal.

Our filter cartridges are designed to provide effective treatment of stormwater while maintaining high flow rates throughout the life of the cartridge. Filter cartridges are available in various configurations allowing you to fine tune performance in terms of sediments and debris, heavy metals, hydrocarbons/toxic chemicals, pathogens/bacteria and nutrients. The lightweight filter cartridge comes fully assembled and snaps securely in place with a quick twist. The modular cartridge design allows quick and easy replacement while containing the spent material for safe transport and disposal.

2-Stage Filtration

Each Fabco filter cartridge is composed of a standard pre-filter section, and a main filter chamber which can be configured to target specific pollutants.

Pre-Filter

The pre-filter is manufactured using FABGUARD antimicrobial treated open cell Polymer foam pads. The coarse open cell foam acts as a mechanical pre-filter for the cartridge restricting coarse sediments, trash and debris while allowing mostly water to flow through. Stormwater passing through the complex cellular structure contacts the antimicrobial treated internal walls substantially reducing the growth and passage of pathogens through the cartridge.

Proprietary Treatment Technologies

Fabco offers 5 filtration configurations (Standard, HV metals, Pathogens/bacteria, HV Hydrocarbons, Nutrients) using a combination of the following treatment technologies:

- FABMAX: This chemical treatment is applied to our open cell polymer foam filtering media. It is hydrophobic and instantly bonds to any hydrocarbons in the water matrix.

- FABSORB: This oil absorbent fabric material is used for treating free and emulsified oils, greases and other hydrocarbon-based compounds. This non-woven, filter can absorb 10 to 20 times its own weight in oil, greases and hydrocarbons.

- FABLITE: This natural mineral compound removes heavy metals as well as low levels of dissolved pollutants like hydrocarbons and other toxic chemicals.

- FABPHOS: This proprietary filtering media treats soluble, ortho-phosphates in stormwater runoff. FABPHOS also is effective in reducing nitrogen compounds thus assisting stormwater managers meet the >40% N reduction required by many states.

- FABGUARD: This antimicrobial shield is a patented chemical technology that when applied to our foam material makes it antimicrobially active. FABGUARD fuses with the material and will not wash out, or leach into the environment. Microorganisms that contact the material are neutralized.

Currently Fabco Industries offers a variety of filter cartridge types which can be used interchangeably in our StormSafe and StormBasin product lines.

10162-44-000 DownSpout Filter BG (2 Cartridge)

10162-27-000 DownSpout Filter BG (2 Cartridge)

10162-19-000 DownSpout Filter BG (2 Cartridge)

10491-2-000 DownSpout Filter BG (Debris Basket 12″ Stubs)

10378-1-000 DownSpout Filter (Debris Basket 18″ Stubs)

10162-26-000 DownSpout Filter (Debris Basket 24″)

10162-26-000 DownSpout Filter (Debris Basket 30″)

10162-37-000 DownSpout Filter (Filter Sack 24″ HARCO)

Fabco Industries is a leader in stormwater filtration treatment products and engineering. Solve virtually any stormwater pollution challenge with our sustainable, simple-to-maintain filtration solutions. Our stormwater products are highly effective for various applications including retrofits, new construction, and green infrastructure.