In an effort to produce high-performance stormwater filter system prototypes in a more timely fashion, Fabco Industries acquired a 3D printer. Previously, Fabco has relied on a rather costly and time-consuming process that involved outsourcing third party companies to build prototypes. With the acquisition of the S-Squared 3D printer, Fabco has brought the work of creating prototypes in-house, effectively shaving a lot of time off a task which previously could take up to 4 weeks to complete.

Now Fabco is in total control over when these stormwater filter system prototypes are completed and when live testing can be performed for a client, making the entire process much smoother and convenient for all involved. There is even a camera on the device that monitors the prints 24/7 to create perfect stormwater filter system prototypes.

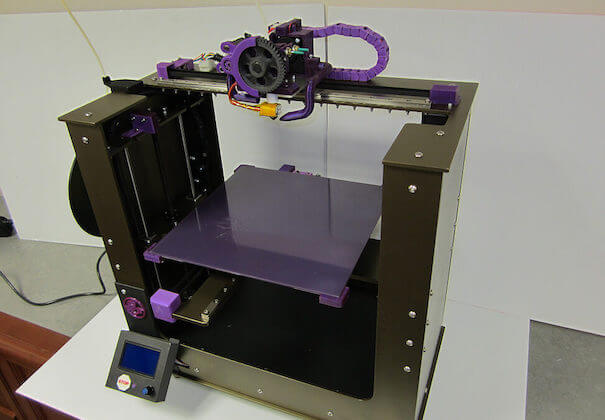

The S-Squared 3D printer bolsters a large printing area, 12”x12”x12”, or one cubic foot of printable area. It also has a unique printer head cooling system that was custom designed to keep extruder cold ends cold and provide material cooling for precision printing. Its low jam extruder nozzle is designed to reduce the incidents of jams from switching materials without switching the nozzle. With an extremely rigid aluminum frame, this machine will not have any chassis flex even under the most demanding printing. In fact, it’s so rigid you may only have to adjust it one time over its lifetime. Fabco Industries and their clients are sure to reap the benefits of having this highly advanced printer in-house very quickly.

3D Printing Reference

The term 3D printing covers a host of processes and technologies that offer a full spectrum of capabilities for the production of parts and products in different materials. Essentially, what all of the processes and technologies have in common is the manner in which production is carried out — layer by layer in an additive process — which is in contrast to traditional methods of production involving subtractive methods or moulding/casting processes.

Applications of 3D printing are emerging almost by the day, and, as this technology continues to penetrate more widely and deeply across industrial, maker and consumer sectors, this is only set to increase.

Most reputable commentators on this technology sector agree that, as of today, we are only just beginning to see the true potential of 3D printing. 3DPI, a reliable media source for 3D printing, brings you all of the latest news, views, process developments and applications as they emerge in this exciting field. This overview article aims to provide the 3DPI audience with a reliable backgrounder on 3D printing in terms of what it is (technologies, processes and materials), its history, application areas and benefits.

Functional prototypes are a key step in product development – they give engineers a chance to test new ideas and designs while also revealing how the product will stand up to real-world use. And when it comes to functional prototypes, 3D printing is rewriting the rules of what’s possible. One of the most important changes made possible with printing relates to speed.

Where it may take weeks or months for traditional manufacturing processes like casting and forging, 3D printers can turn out parts in just days. For manufacturers, that translates into the ability to create not just one or two prototypes of a particular part, but many.

By creating multiple prototypes with subtly different geometries, it’s possible to test them simultaneously and quickly refine the design. Printed parts can also be far more complex than their traditional counterparts, allowing designers to precisely tailor features and geometry to maximize part performance.

That complexity enables the use of generative design tools to create highly-optimized, organically-inspired geometries that would be difficult – or nearly impossible – to manufacture with traditional methods. With less material waste and no need for a dedicated, skilled operator, printing prototypes can be less expensive than traditional manufacturing.