Infiltration is one of the basic unit processes for controlling stormwater runoff volume management. An ancilary benefit of stormwater infiltration is water quality treatment.

Infiltration best management practices (BMPs) are generally built as either above grade basins or below grade chambers (pipe and stone, concrete, plastic arches or boxes, etc.). Both methods are effective and have common benefits. They also share common performance and maintenance issues. Infiltration provides a mechanism to control runoff volume by infiltrating it back into the ground. Infiltration best management practice solutions (especially chambers) also inherently provide some beneficial aspects to flow rate, water quality, stream bank protection, flooding, thermal impacts and groundwater recharge.

The use of infiltration best management practice solutions gained popularity in the mid 2000s. Maryland, New Jersey, and Pennsylvania were some of the first states that rolled out technical guidance that included infiltration as a stormwater management BMP.

The Philadelphia Water Department (PWD) has gained national recognition as a champion of progressive “Green Infrastructure” with the roll out of their “Green City, Clean Waters” program in 2011, which was a progressive approach towards their CSO Long Term Control Plan. To meet state and federal regulations, one aspect of the plan reduces the volume of stormwater entering the combined sewers through the use of “Green Inlets” that convey runoff to volume reducing BMPs. All PWD “Green Inlets” incorporate a Fabco type of geotextile-based water quality insert (WQI) that capture particulate pollution from the runoff.

Infiltration Facility Performance Issues

While they have different design aspects, basins and chambers share some potential short falls in terms of performance and sustainability. Pretreatment is an approach that will provide solutions to performance and sustainability issues. While serving as Chief, Construction Permits Section, Waterwars and Wetlands Program PA DEP- SERO, Domenic Rocco P.E.‘s provided a presentation on “Infiltration Best Management Practices” in 2012 which stated:

- “Loading Ratio: A rule-of-thumb approach for sizing infiltration BMPs…intended to prevent hydraulic and pollutant overloading and sustaining a reasonable design life.”

- The 2006 Pennsylvania BMP manual “doesn’t mandate pretreatment.”

- “However, SWM has evolved to a point where it (infiltration pretreatment) is imperative for sustainability.”

- “Pretreatment is most critical for subsurface infiltration systems.”

- “Target parameters: Oil/Grease, trash, TSS, Phosphorus, Nitrates.”

- “No Pretreatment” was listed as the number one bullet point in terms of High-Risk infiltration BMP design approaches.

Domenic Rocco P.E.

Below is a brief overview of the most common infiltration best management practice issues and a corresponding overview of Fabco solutions to enhance performance and sustainability of these facilities. The topic of infiltration BMP design (including sizing criteria) is broad and ever changing based on continuous advancements in the stormwater profession. The scope of this blog is to focus on a few specific aspects of the larger picture – for project specific feedback, please contact Fabco Industries or our nationwide distribution network.

One of the main principles of the information presented is prevention first, and mitigation second. It is more expedient to prevent the problems from being created with pretreatment design than to mitigate the effects of the hydraulic and pollutant overloading after the fact.

Clogging of Conveyance Infrastructure – Regardless of the design, the stormwater runoff that the BMPs are designed to address is generally collected and transported through some combination of inlets and pipes. If the system’s delivery infrastructure (or plumbing) prevents the runoff from getting to the infiltration interface, then the intent of the system is undermined. The target pollutants, associated with this specific topic is trash and debris, or gross solids, such as plastic bottles and sandwich wrappers, leaves, etc.

Clogging of Infiltration Interface – “Infiltration systems are among the most commonly implemented practices to control urban stormwater and to attenuate pollutant delivery to receiving waters, because they are relatively cheap to build and amenable to space constraints in urbanized areas.” However, infiltration systems tend to clog with sediments, which can rapidly reduce their performance. This specific topic adds soil sediment particles into the equation – while they may be too small to clog the conveyance of stormwater to the infiltration BMP, they will clog the actual soil interface.

There are no natural processes to aid in rejuvenating the soil’s permeability once it’s compromised. As any area of the soil interface becomes clogged, the remaining interface area comes under additional pressure to deal with the infiltration volume.

Pollution of Groundwater – Impervious land cover is a major source of stormwater runoff. Depending on the land use of drainage area, the approach of routing a large drainage area footprint into a considerably smaller infiltration footprint can result in an overload of pollutants which can impact groundwater. In addition to the soil sediment particles, this topic now introduces “dissolved” pollutants into the equation.

Fabco Stormwater Infiltration Best Management Practice System Solutions

Pretreatment is essential for sustainability (extend the functional life) and to increase the pollutant removal capability of an infiltration best management practice. Based on the outlined factors and mechanisms contributing to performance decline of infiltration best management practice solutions, Fabco Industries’ filtration devices provided a simplified approach towards proactively addressing those factors.

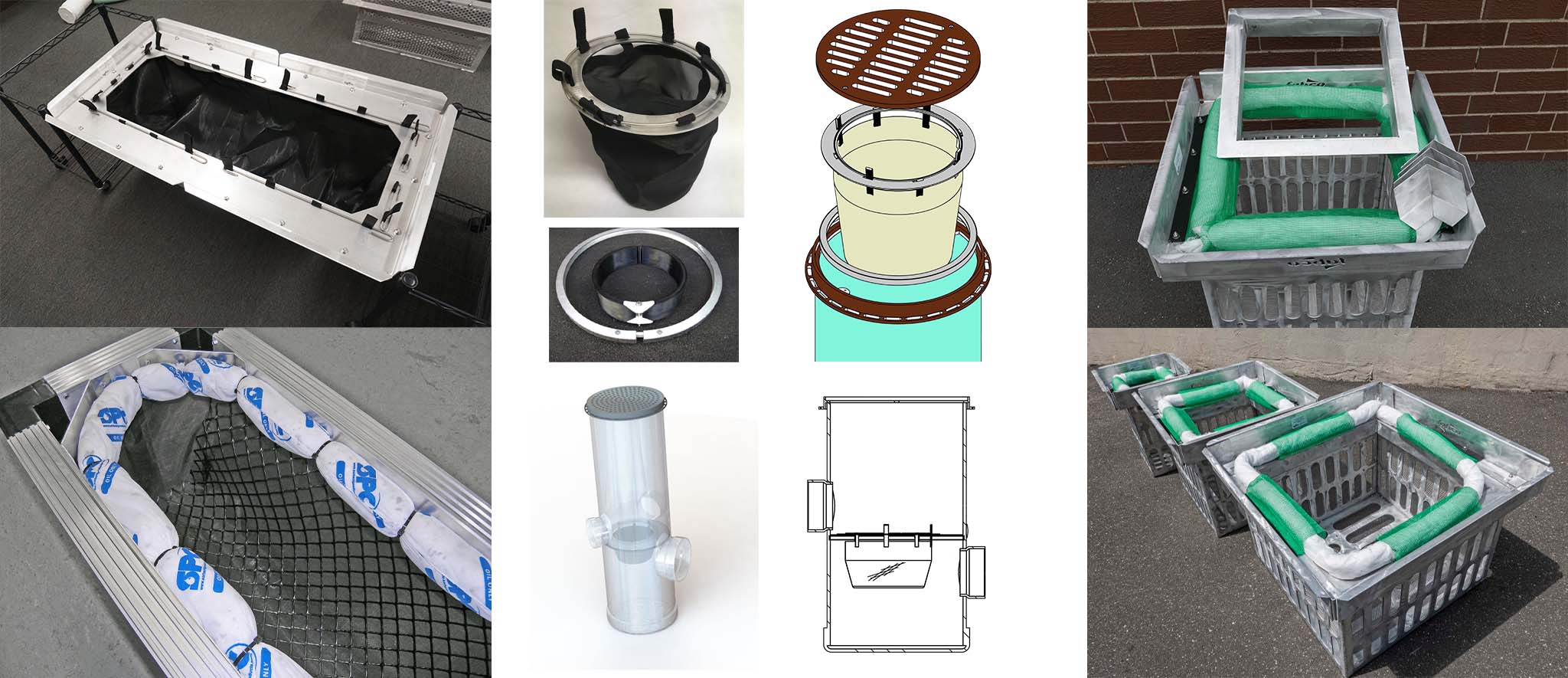

Clogging of Conveyance Infrastructure – Post construction stormwater runoff varies from site to site but generally always contains gross solids (trash and debris). Connector Pipe Screens (CPS) can convert existing inlets into decentralized pre-treatment structures.

Above Left: Connector Pipe Screens (CPSs) can be made from perforated stainless steel with pollutant target specific hole diameters (3/16” openings shown as example of target pollutant being down to a cigarette butt.)

Above Center: CPS units can be fabricated for a wide variety of inlet sizes and configurations. Oil absorbent booms or flaps can be incorporated to expand the ability of the units to capture another common runoff pollutant, Hydrocarbons (see inserts).

Above Right: Fabco product innovation has led to the creation of the “Expanding StormRing CPS”, a user friendly unit that mounts inside the inlet discharge pipe rather than being bolted to the inlet wall – easing inlet fit, maintenance, and down stream pipe access considerations.

Above Left: Example of inlet basket protection designed for NYCDEP inlets that convey runoff to adjacent infiltration BMPs under surrounding sidewalk.

Above Center and Right: Fabco manufactures a perforated basket filter for a variety of sizes of plastic basins.

Fabco StormSack and ScreenBox as Infiltration System Solutions

The Fabco StormSack product line typically incorporates a UV stabilized woven polypropylene monofilament geotextile fabric, with an Apparent Opening Size of 40 US Sieve, or approximately 420-micron. This geotextile fabric has proven to be very effective in reducing sediment loading generally associated with clogging infiltration BMP’s. Specifically, this woven monofilament geotextile is made up of individual filaments that are woven together in a screen-like fashion to create a very high strength fabric with a large Percent Open Area (POA) to maintain the required design filtered flow rates.

It is also noteworthy to mention that smaller particulate tends to adhere to larger sediment and gross pollutants which are captured by the geotextile fabric.

Clogging of Infiltration Interface – As the target pollutant changes from gross solids clogging the conveyance to the storage component of the infiltration BMP the focus now must include particulates that need a finer filter component to capture these smaller particles. Fabco’s StormSack Series of Geotextile Bag and ScreenBox Aluminum Screen Water Quality Inserts have the finer filter characteristic to capture many potential clogging sized particles. This issue can be more comprehensively addressed with the Fabco Filter Cartridges presented in the next section.

Above Left: The StormSack series is available to fit a wide variety of inlet configurations with different features that lend themselves to either hand or vac truck maintenance.

Above Center: Fabco geotextile filter bag options are available in many sizes and applications, from Rain Garden bypass to plastic basins with larger diameter geotextile bags or even centralized vaults.

Above Right: Fabco’s ScreenBox units incorporate a combination of an aluminum frame and screens to capture >80% TSS.

In addition to typical sediment loading discussed, there is also the potential for dissolved pollutants to be present in the stormwater and conveyed into the infiltration BMP. These non-sediment pollutants can be of significant quantity, and include Bacteria, Nutrients, Hydrocarbons and Heavy Metals just to name a few. For these non-sediment pollutants, Fabco offers a line of cartridge filters. These targeted replaceable filters provide effective treatment of stormwater while maintaining very high flow rates. In this same vein, Fabco also offers a unique, third party tested, Sediment Control Cartridge (SCC) capable of reducing extremely fine particle loading by 80%.

Testing for the SCC cartridge was performed using an approved NJCAT/NJDEP sediment gradation matrix.

Pollution of Groundwater – Centralized or Decentralized Cartridge Based Devices as Infiltration System Solutions

In dealing with the over-pollution of groundwater, not only do particulates and their “piggy backed” pollutants have to be addressed, but there are also considerations of reducing “dissolved” pollutants. Fabco Filter Cartridges incorporate a combination of proprietary media that can target TSS or other specific pollutants of concern (nutrients, bacteria, heavy metals, fine sediment, hydrocarbons, etc.).

Above Left: Conceptual cross section of a Fabco Filter cartridge.

Above Center and Right: Fabco Filter Cartridges are basically the ”engine” that drives higher pollutant removal efficiencies. The cartridges can be deployed in a variety of centralized or decentralized devices. Contact Fabco Industries or one of our nation-wide distributors for your project specific needs.

In summary, Fabco Industries is a leader in providing options for pretreatment. We are here to help anyone that may be seeking alternatives to achieving stormwater compliance including BMP loading ratio adjustments or waivers from local stormwater requirements on a project specific basis.

Click Here to learn more about our products

References:

A Risk based Approach for Sizing Stormwater Infiltration BMPs – Domenic Rocco, P.E., PADEP)