Waynesboro, Virginia is a small designated river city that boasts a thriving industrial sector while only a few miles from the famous Shenandoah National Park and the Appalachian Trail. Understandably, the city’s managers want to keep business moving while preserving the national wonders that Virginia is known for.

That’s why the City of Waynesboro Stormwater Program took an interest in an open curb roadway inlet that had been affected by hydrocarbons in stormwater runoff coming from a food oil and grease disposal site used by local restaurants upstream from the inlet. The issue was caused by spillage of the residual waste that was conveyed to the inlet in a first flush manner, and it was important to find a solution as this drain flows directly to the south river right off of main street.

This non-point source contaminated runoff could be treated by a Fabco Filter Cartridge but still needed a decentralized retrofit device that did not yet exist to implement the cartridge.

Finding a Solution to Hydrocarbons in Stormwater Runoff

Fortunately, Ferguson representative Robert Connelly was familiar with Fabco Industries. He knew that the job required a very specific hydrocarbon target pollutant filter cartridge, and he knew that Fabco’s engineers could design and create a retrofit that could address the issue, and be installed and easily maintained.

Robert presented the Fabco Filter Cartridges to Jennifer L. Allen-Key of City of Waynesboro, VA. She saw the benefits of a custom-designed solution for a problematic inlet and gave the project the go-ahead.

Although many manufacturers would consider this job relatively small and not worth pursuing, Fabco excels at these retrofit challenges. This particular project actually required two aspects of Fabco’s unique market offerings: a target pollutant-specific filter cartridge and the fabrication expertise to manufacture a device that could fit into the inlet through the small man-hole access and then be properly installed for long project life.

Robert Connelly II, Geo Specialist at Ferguson Waterworks

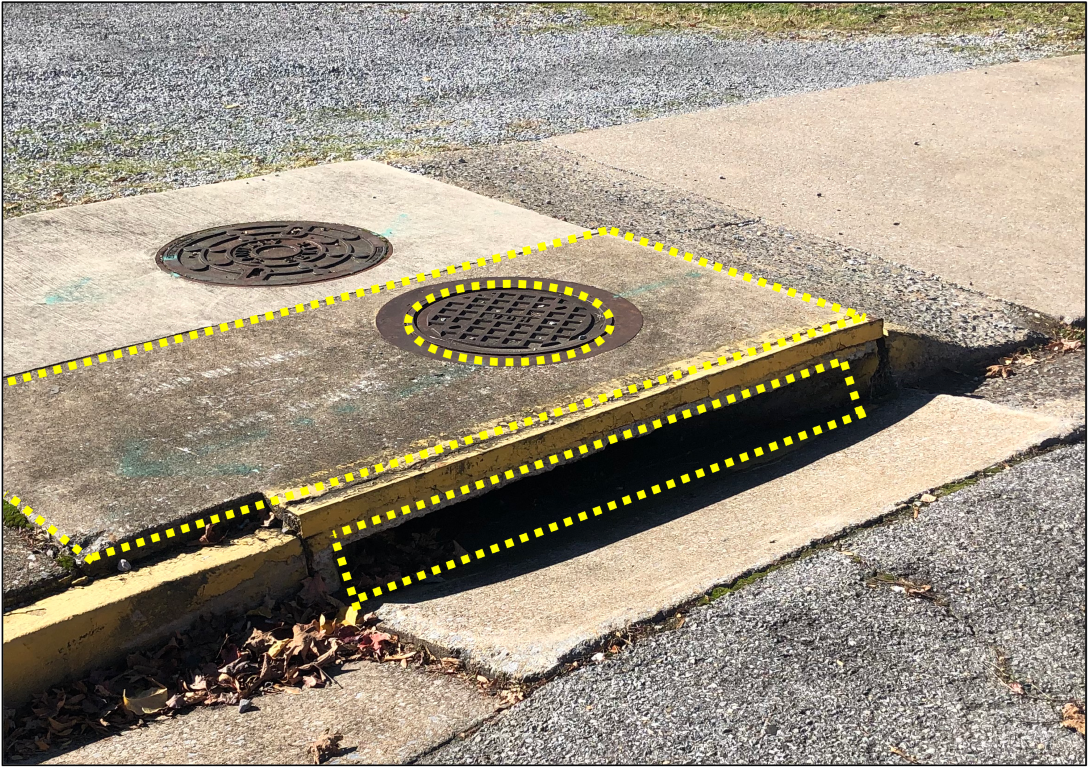

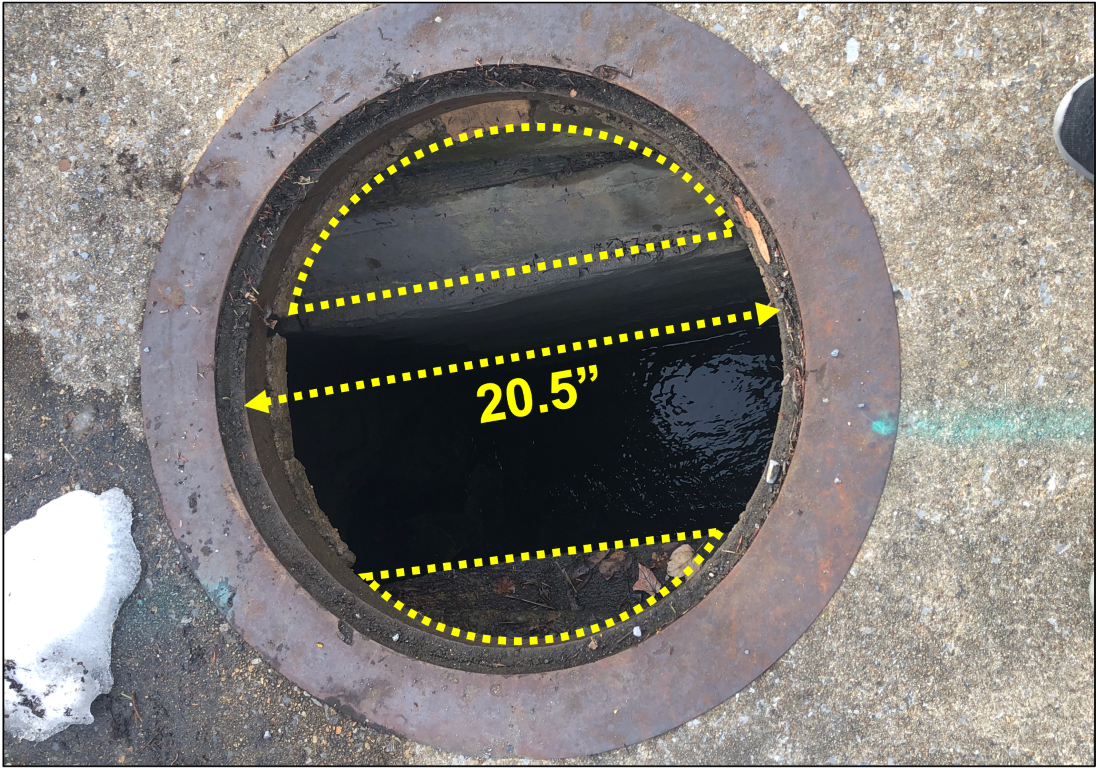

The inlet of interest had limited access – the shallow curb throat opening was too small to use, so the StormBasin, cartridges and brackets would have to fit through a 20.5″ manhole opening. The two existing ledges in the interior of the structure made the design even more challenging.

Practically Treating Hydrocarbons in Stormwater Runoff

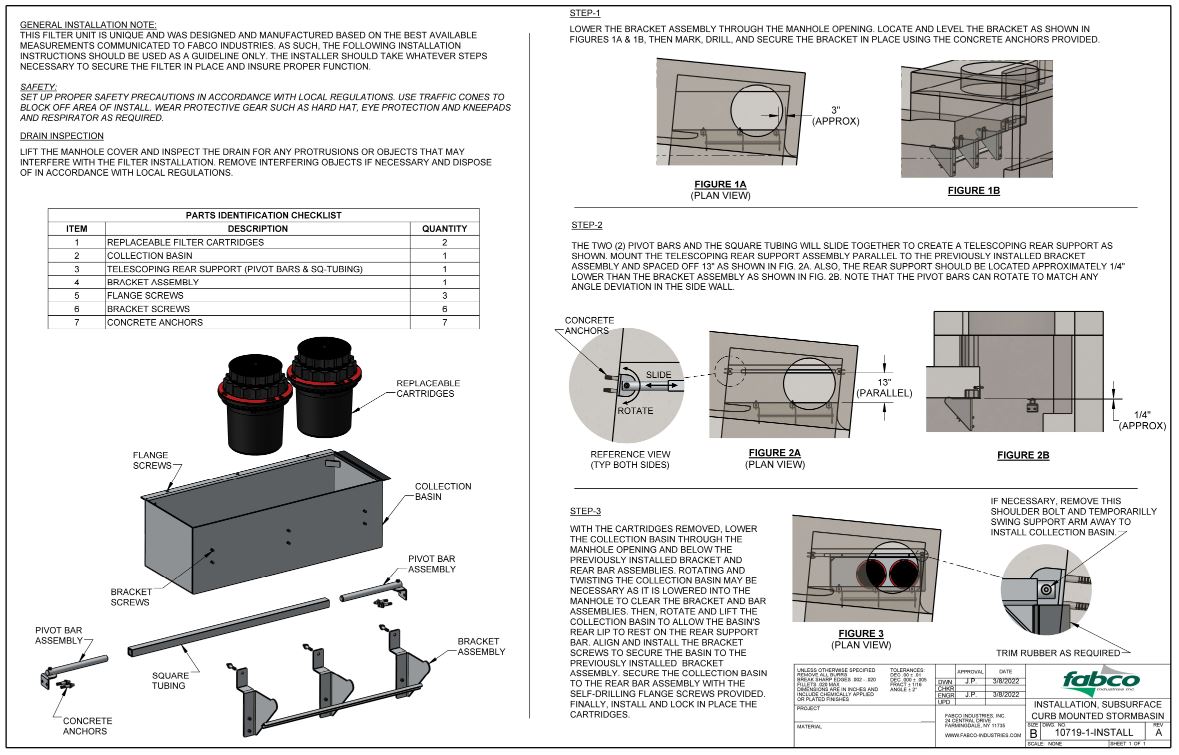

The process started with a survey of the existing inlet to provide the Fabco engineering team with the parameters to follow in designing the retrofit device. Based on the survey results, Fabco fabricated the custom StormBasin Cartridge Based Filter unit and also created an installation guide unique to this product and project. A remote pre-construction meeting was conducted in which Fabco engineers, the Waynesboro Stormwater crew and supervisors as well as a Ferguson representative reviewed the design and installation.

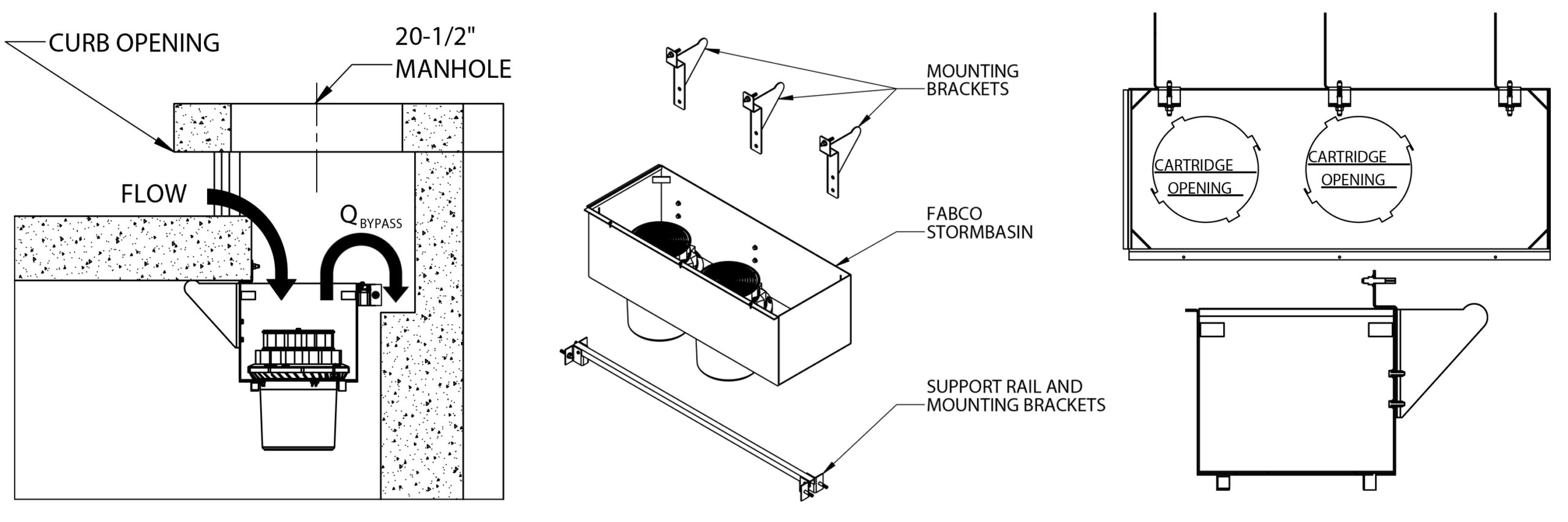

Fabco provided a top drawing of the StormBasin as well as the customized installation guide created for this device, shown above.

The exacting design and preconstruction activities paid dividends as the only real challenge for this project was drilling into very old, very hard concrete to install the anchors. Fabco has set up a potential remote support call if needed, but the crew completed the install without any additional support.

Note the body of the StormBasin was designed to fit through the 20.5” manhole. In order to get the device installed and still get out of the inlet structure, some innovative techniques were employed by the crew.

Left: StormBasin body in place – note that both cartridge openings are off-set to one side to provide future maintenance access. Right: First of two Fabco Hydrocarbon Cartridges (blue rings) in place.

The whole process from initial inquiry to completed install was done in under five months. Robert Connelly of Ferguson Waterworks stated “I was thrilled at the amount of effort Fabco and their team put into ensuring this single inlet installation for a small city hundreds of miles away was a success. The customization of this particular unit and the entry was unique and quite complex. Although they were challenged, our install went in without any further alterations!” Overall, the project was a major success.

Click Here to learn more about our products