Enhance Rain Garden Performance

In an ideal world, communities could rely solely on engineered Rain Gardens to catch, filter and release pollutant free stormwater runoff into the environment. In reality, a combination of both the bioretention aspects of Rain Gardens and innovative technological stormwater solutions (grey infrastructure) can enhance rain garden performance and deliver consistent and comprehensive contaminant removal.

Rain Gardens provide stormwater management, both water quality and water quantity benefits in a number of ways, specifically:

Filtration – Different specific mixes of soil and/or sand-based media filter (or adsorb) pollutants out of the runoff as it flows through the media to provide a water quality benefit.

Biological Uptake and Evapotranspiration – The root system of plants in the Rain Garden absorbs the runoff and release it through their leaves, providing a water quantity or volume benefit.

Consider a Rain Garden (also called a biocell or bioretention). Expertly determined soil/sand-based media and strategically planted trees and bushes will catch and clean stormwater before infiltration or discharge into the environment. While this method is effective, it has problems. Firstly, most of the filtration is done by the plant roots both by straining and water absorption. A relatively new Rain Garden may not have the root development necessary for efficient filtration, as the roots do most of the work of both cleaning the water and opening the media for higher treatment rates. Secondly, this green method may not have the capacity to handle flashfloods or high volume and flow rainstorms that sweep large amounts of debris into the system.

Some designers attempt to solve the latter problem by rerouting the overflow into some type of overflow bypass system. While there is no single approach to overflow system routing, many designs will discharge the untreated overflow into the environment. This violates the basic concept and intent of the Rain Garden approach. Routing the untreated bypass into an infiltration bed creates a different set of issues that will be addressed in the next Fabco Blog (stay tuned).

Rain Garden Performance Issues

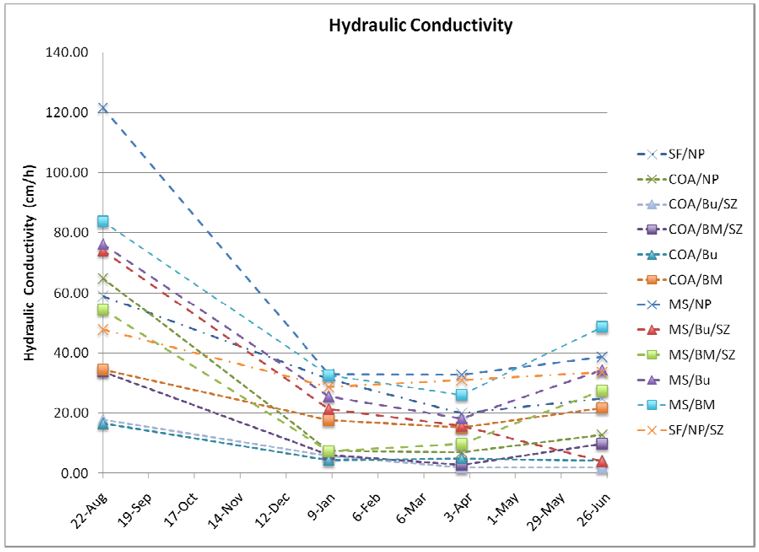

A common component of these systems is the vegatation aspect that enhances performance and provides sustainability of the system. A commonly overlooked sizing aspect of Rain Gardens is that the vegetative root system can take months (or years) to fully mature (see Hydraulic Conductivity graph below), delaying the system treatment capacity. The lack of root system maturation limits the treatment efficiency of the system and leads to a larger volume of the design storm water quality volume bypassing the treatment while flowing into the system’s overflow or bypass system.

The graph above illustrates the evolution of the Hydraulic Conductivity of various soil/sand based biocell media. All media tested show a similar pattern of initial decline, leveling off and then increasing conductivity as the root system matures.

Fabco Rain Garden Solutions

Recently, Robert Woodman, National Urban Green Infrastructure Manager at Ferguson Waterworks, conducted a survey for designers of green infrastructure. In one of the survey questions, Woodman asked “How is bypass of larger storms provided?” The options to select from were as follows:

- No bypass is provided in my designs

- External bypass is provided (i.e. the systems spill back into the street and travel to a downstream inlet) or

- Internal bypass is provided within the asset in the form of an overflow riser.

77.6% of those who completed the survey selected option 3) concluding that internal bypass risers are the most common approach to managing events that exceed the capacity of the Rain Garden.

Generally, a Rain Garden bypass will consist of a plastic riser pipe or basin with a beehive grate incorporated for protection against large debris. In some designs a concrete riser system with a steel grate may be incorporated into the rain garden. Fabco set out to significantly enhance the performance of Rain Gardens with “grey”—or man-made—filtration systems.

To do this, Fabco engineers had to develop stormwater filtration devices that work with existing or planned green infrastructure. They did so by analyzing the real-world performance aspects of Rain Gardens. The main issue that had to be addressed was how to handle significant volume. This is a critical issue because too much volume can result in untreated stormwater being released into the environment.

The heart of Fabco’s solution to enhance Rain Garden performance depends on the structures used for the bypass infrastructure and the level of water quality treatment desired. Fabco options include geotextile or cartridge-based treatment options. The geotextile options will capture TSS, trash and debris and significantly reduce the particulate associate pollutants inherently attached to those particles (nutrients, heavy metals, hydrocarbons, bacteria, etc.). Fabco cartridge options provide a significantly higher degree of particle capture and additional pollutant reductions to enhance Rain Garden performance.

BMP (Best Management Practices) insist that stormwater treatment either maintain and protect existing water quality or be more protective than required. Fabco aims for the latter, working with existing Rain Gardens to allow both biological and technological solutions to a dire environmental problem. With Fabco’s highly adaptable and customizable products, younger biocells can mature without risking water contamination. Mature Rain Gardens can provide aesthetically pleasing environmental conditions while underground filtration exists as both an emergency containment system as well as boosting the level of runoff water quality.

Historically, designers and regulators have seen these bypass enhancements as only a temporary measure pending full root system maturation. But beyond maturation of the Rain Garden they provide ongoing permanent protection to trap floatables, mulch, debris, trash and other pollutants of concern during frequent extreme events that exceed the capacity of the healthy, functioning Rain Garden.

Above Left: Example of standard round Rain Garden bypass pipe riser.

Above Center: Fabco geotextile filter options for bypass pipe risers. “Beehive Filter” kits consist of an aluminum expanding ring and geotextile bag. The Beehive Kits can retrofit to round or square grates.

Above Right: Fabco Filter Cartridge options for bypass pipe risers. When a higher standard of water quality treatment is desired a Fabco Filter Cartridge can be deployed via a “StormPod” in pipes with a diameter of >24”.

Above Left: Example of standard Rain Garden plastic bypass basins.

Above Center: Fabco geotextile filter options for standard Rain Garden bypass plastic basins include larger diameter geotextile bags or perforated metal baskets.

Above Right: Fabco Filter Cartridge options for Rain Garden bypass plastic basins include the DownSpout Filter for decentralized pre-treatment.

Above Left: Example of standard Rain Garden bypass concrete structures.

Above Center: Fabco geotextile filter options for Rain Garden bypass concrete structures include the StormSack BMP series of inserts. Options include a lined bag and/or oil boom if desired.

Above Right: Fabco Filter Cartridge options for Rain Garden bypass concrete structures in include the StormBasin BMP inlet for decentralized pre-treatment in rectangular concrete structures.

Ultimately, the future of the stormwater treatment is a blend of biocell design and manufactured treatment infrastructure. Both can be tailored for specific environments and geographical needs to enhance rain garden performance.

When considering Rain Gardens and/or infiltration chambers for your stormwater management design, consult with the experts at Fabco Industries. By reviewing your needs and current stormwater infrastructure, the team can show you unique and effective system enhancement options. They can also discuss any extreme weather or environmental conditions that your solution might be called upon to handle.

For more information, feel free to fill out our web inquiry form, reach out to sales@fabco-industries.com or give us a call at 631-393-6024.