Project Profile – Bloomer Road to U.S. 6 Stormwater Retrofit

Project Owner: East of Hudson Watershed Corporation (EOHWC)

Engineer of Record: Nathan L. Jacobson and Associates, P.C.

Contractor: Brennan Construction Company

Reduce Phosphorous In Stormwater With Fabco Industries

Brewster Heights was required to reduce phosphorous in stormwater. This is a community that occupies approximately a half a square mile in the Town of Southeast in southern Putnam County, NY. required to reduct phosphorous in stormwater.

The East of Hudson Watershed Corporation is a local development corporation established by the municipalities in Northern Westchester, Putnam, and Dutchess Counties in the New York City Watershed. Its aim is to install stormwater retrofit projects to meet the requirements to reduce phosphorus in stormwater as defined by the New York State Department of Environmental Conservation (NYSDEC).

The Corporation works in conjunction with the NYSDEC and New York City Department of Environmental Protection (NYCDEP) to further Stormwater MS4 quality projects in the Croton and Kensico Reservoir Basins.

Ultimately, the driving force behind the stormwater quality improvement is protecting New York City’s filtration avoidance determination and its drinking water supply to reduce phosphorus in stormwater.

Fabco Industries is a NYS based manufacturer of quality stormwater treatment devices with over 5000 installations in NYS alone.

This project to reduce phosphorus in stormwater involved the collaboration of multiple parties over the course of the last decade. The initial goal of the project was the stabilization of four heavily eroded channels which discharged runoff from the Brewster Heights subdivision. These channels had caused severe washout and sediment deposition onto private property and into the New York City water supply Middle Branch Reservoir.

While the stabilization of the eroded channels was straightforward, identifying an appropriate water quality Best Management Practice (BMP) to implement proved challenging. One of the last design iterations prior to approval from the NYCDEP involved the installation of two Hydrodynamic Separators (HDS), individually located at the outfall of the two channels where runoff was to be rerouted. The location of these units would have required realignment of multiple existing utilities and taken up a significant footprint within the right-of-way in an effort to reduce phosphorus in stormwater.

The existing phosphorus load to reduce phosphorus in stormwater from the drainage area tributary to the stabilized channels was calculated as 22.46 kg/yr. The reduction credit which was attainable through installation of two HDS units would have been 2.25 kg/yr. The estimated installed cost was between $80,000 and $100,000, not taking into account the required realignment of existing utilities.

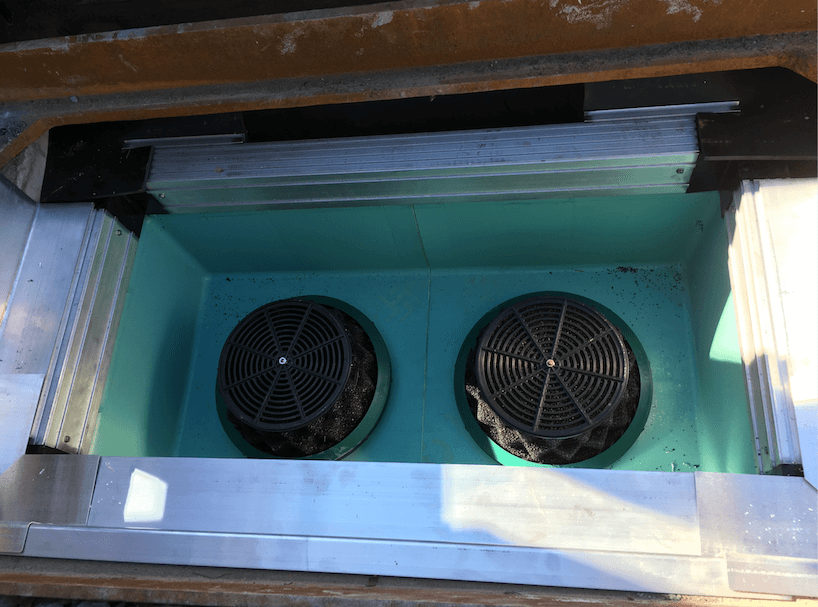

Enter Fabco Industries and the StormBasin solution. This BMP had previously been approved by the NYSDEC to provide 50% reduce phosphorus in stormwater at its peak treatment flow rate. It also had the advantage of offering the ability to be retrofitted into existing catch basins to reduce phosphorus in stormwater.

The NYSDEC’s approval was based on the comprehensive technical submittal prepared by the engineering and science consulting firm Woodard & Curran, as part of the overall East Of Hudson Coalition Stormwater Retrofit Plan. Woodard & Curran collaborated with NYDEC to consider approving additional stormwater retrofit treatment practices into the overall NYC water supply phosphorus reduction program. This allowed municipalities within the EOH watershed additional options to treat and reduce phosphorus in stormwater runoff prior to discharging into the NYC reservoirs.

Based on a thorough review of the stormwater retrofits approved by NYSDEC and installed to date, Woodard & Curran strongly believed that in order for the overall phosphorus reduction program to be successful, the regulated municipalities needed cost-effective and easy-to-implement stormwater retrofit treatment solutions that also required minimal O&M.

After a thorough review of various stormwater treatment retrofit practices available in the marketplace that had not yet been identified or approved by the NYSDEC as acceptable treatment practices to reduce phosphorus in stormwater within the EOH phosphorus reduction program, Woodard & Curran saw the promise that the STORMBASIN SOLUTION WITH FABPHOS FILTRATION MEDIA offered the municipalities.

Steven Lauria, PE, Project Manager and Principal of Woodard & Curran, stated: “The first five years of retrofits revealed that for the program to be successful moving forward, there needed to be cost-effective and low maintenance retrofit solutions that did not require the modification of existing infrastructure or land disturbance. One of the greatest challenges of implementing retrofits on public and private property is limiting the impact to existing infrastructure, property, and current operations. The StormBasin solution met all the challenges of the retrofit model as a cost-effective and low maintenance solution. StormBasin has the potential to save the EOHC millions of dollars when compared to other NYSDEC approved retrofit practices.”

Treating a fraction of the drainage area, the StormBasin inserts were able to obtain a reduction of 7.43 kg/y—and at less than one third the installed cost of the HDS solution to reduce phosphorus in stormwater. Most impressive was that it did so with no required realignment of existing utilities!

Treating a fraction of the drainage area, the StormBasin inserts were able to obtain a reduction of 7.43 kg/y—and at less than one third the installed cost of the HDS solution to reduce phosphorus in stormwater. Most impressive was that it did so with no required realignment of existing utilities!

The decentralized nature of the StormBasin solution being both “at grade” and “at source” has several advantages over a buried downstream device. StormBasin installations are easily inspected and maintained at grade and once installed can protect the downstream infrastructure.

Said Kevin Fitzpatrick, Director of Engineering for the EOHWC, “Fabco Industries and Bill Stoecker were attentive and responsive throughout the entire project to ensure we had the best solution in place to fit the Corporation needs.”

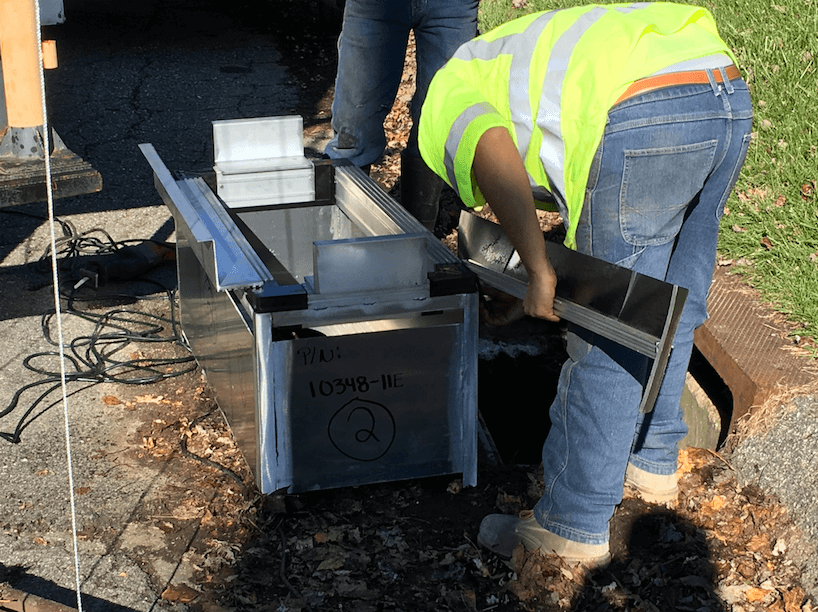

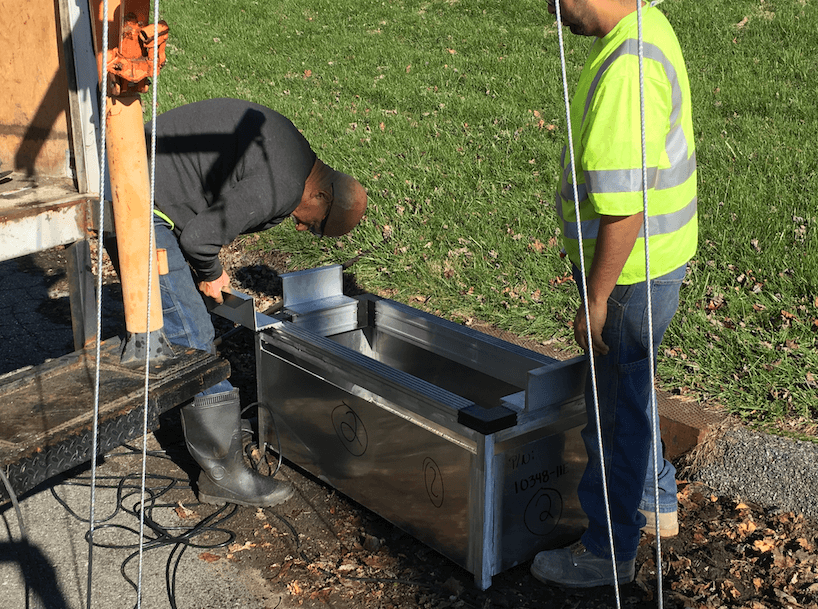

14 Fabco StormBasin Units with a total of 29 cartridge filters were installed by Fabco Industries’ team over a two-day period in November 2018. Several different styles of units were utilized to accommodate the various catch basins, frames and grates that exist in the community.

The long-term success of these installations relies on the timely approach to maintenance of the drainage area and the catch basins themselves. To this end, StormBasin units have been designed to make biannual cleaning and annual replacement of the cartridge easily done by any local workforce.

Looking to the future, StormBasin is to be implemented in several EOHWC projects. This solution should be considered in any situation where water quality improvement is needed, economics is a driver and ease of inspection and maintenance is desired.