Catch basin filter inserts provide solutions to the towns stormwater pollution. The Incorporated Village of Patchogue and the Town of Brookhaven located in Suffolk County, Long Island announced details of an innovative stormwater partnership project on May 29th 2014.

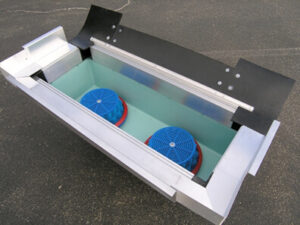

The two-year pilot program will utilize Fabco Industries Stormbasin™ catch basin filter inserts in town-owned basins with a direct discharge to tributaries draining into the Great South Bay segment of the Long Island South Shore Estuary Reserve.

The basins are located within close proximity to the village boundaries, and will be maintained and monitored by the Village of Patchogue during the duration of the program. Data collected will be shared with the Town and will be provided to the New York State Department of Environmental Conservation as a minimum control measure best management practice consistent with the municipal separate storm sewer system (MS4) general permit conditions allow for catch basin inserts to be installed.

The Fabco Stormbasin™ catch basin filter inserts will capture a variety of pollutants from stormwater runoff including floatable debris, contaminated sediments, hydrocarbons, and bacteria that would otherwise discharge directly to the streams and Bay with every precipitation event. Three priority Great South Bay tributaries have been targeted for the project including Corey Creek, Tuthills Creek, and the Swan River with catch basin filter inserts.

The Stormbasin™ catch basin filter inserts are a proprietary product of Fabco Industries, who worked in partnership with the Village and Town to develop and initiate the pilot project.

“We are confident that this partnership will clearly illustrate the effectiveness of applying proprietary stormwater filtration techniques with catch basin filter inserts in a watershed based and targeted manner to improve water quality in the south shore estuarine environment and throughout our beautiful coastal region” said Jeff Fullmer, Fabco Watershed and Regulatory Services Coordinator.

Catch Basin Filter Inserts Reference Material

A catch basin insert is a device installed in a storm drain to provide water quality treatment through filtration or absorption. Catch basin inserts fit into existing catch basins and are configured to remove one or more of the following contaminants: coarse sediment, oil and grease, and litter and debris. Some units may be able to remove dissolved pollutants and pollutants associated with sediments. When selecting an insert, ensure that your specific pollutant–removal needs are met.

As with any treatment BMP, catch basin inserts should never be used in place of source control practices. Oil and Grease Removal: Inserts designed for the removal of oil and grease contains, and depends on, oil–absorbing media. The King County Surface Water Design Manual (SWDM) requires specific materials/media to be used in catch basin inserts to ensure oils are not re–released during storm flows. These inserts are appropriate for use in any area in which vehicles are used, maintained or stored.

Because of the small storage capacity of these inserts, they are not acceptable as the sole line of defense against actual oil spills in areas where large amounts of oil could be released. Large amounts of sediment entering the catch basin significantly reduce the effectiveness and longevity of the oil absorbing media.

Under these conditions, an oil/water separator with a pre–settling chamber may be more appropriate. Sediment Removal: Inserts designed for sediment removal may be used at construction sites and in situations where stockpiles or unpaved areas are likely to contribute high sediment loads. They may also be appropriate for small (low traffic) businesses. They are not considered a substitute for other source control BMPs.

Debris Removal: Inserts can also be used for the removal of litter and debris, particularly leaf and tree material. Design and Maintenance Unlike most other treatment BMPs, which must be designed and constructed specifically for your site, catch basin inserts may be purchased directly from a vendor and installed by the user.

While standardized insert units are available, most vendors are able to customize their systems for your site. Before purchasing a catch basin insert, the following factors must be considered.

Conveyance Capacity: The conveyance capacity refers to the amount of water that the insert can pass without causing flooding. This capacity is equal to the amount of water that is able to pass through the insert’s treatment area, plus the amount that can pass through the built–in overflow.

Over time, the treatment area begins to clog and the total conveyance capacity is reduced. If maintenance is neglected or if the insert captures an unusually high amount of sediment or debris, the treatment capacity may drop to zero and all of the water will have to drain through the overflow (routine inspections help prevent Storm water Pollution Prevention Manual • King County 97 this problem).

In order to minimize the chance of flooding, the insert should function as designed and be able to handle flow from the area draining to the catch basin. The vendor should be able to tell you what the conveyance capacity is. Don’t allow employees to poke holes in the insert to drain flooded areas. Treatment Capacity and Bypass:

The treatment capacity refers to the amount of storm water that the insert unit will pass through its treatment area. The insert unit should be sized to ensure that most of the water entering the drain inlet is treated even as the treatment area starts to clog.

The ability of the insert to remove pollutants will be reduced if water is able to seep between the storm drain grate and the edge of the pavement. Ensure that this gap is sealed. The vendor should provide you with information on how to prevent this situation and information on the treatment capacity of the system.

Maximum Weight: The maximum weight of the insert/filter will be equal to the weight of the insert/unit when new, plus the weight of the sediment and water trapped in the unit. Under the most extreme cases, the treatment area of the insert/unit may become completely clogged, and the unit may be full of water when it comes time to service it.

It is essential the maximum weight of the insert be less than what can be lifted by the people or equipment to be used during maintenance. Before ordering a system, or having a system customized to your site, be sure the vendor knows how you will be removing the insert/unit for maintenance.

Maintenance: Since the installation of one or more catch basin inserts represents a long–term commitment to maintenance, it is important that the unit selected be easy to use and maintain, and that it is built to last. Be sure to have the vendor provide a complete demonstration of the product at your site, and if possible, ask to try an insert before committing to its purchase.

Catch basin inserts are ineffecective without adequate maintenance. Frequent inspection of the insert is necessary. Actual maintenance will generally consist of removing the insert from the catch basin, emptying accumulated sediments, cleaning or replacing the filter media (if applicable), and re–installing the insert. In most cases these materials may be disposed of as regular solid waste, however, media used for oil and grease removal may require special treatment.

See the Disposal Information Sheet for more information. Maintenance frequency will vary depending on the site and on the amount and type of pollutant targeted for removal. All units should be inspected every one to two weeks (except during periods of dry weather), and complete maintenance performed whenever necessary. The simplest way to determine whether the units need maintenance is to inspect them during a rainstorm and see whether water is exiting the overflow.