Measuring Open Curb Manhole Pipes and Protrusions

Review Information Needed on Open Curb Manhole Pipes and Protrusions and Recording it on the Survey Form

All Fabco Industries Water Quality Inserts (WQIs) are manufactured to properly fit inlets by using specific information compiled in a survey of the “as-built” inlet. The Fabco Open Curb Manhole form serves as the tool to provide that information.

Measuring Open Curb Manhole Pipes and Protrusions

Every inlet will have a minimum of at least one pipe (to discharge the flow). Some inlets may have multiple pipes. It is important for Fabco to understand the size and location of the inlet pipes, even if they do not protrude into the inlet open space as the Fabco filter device should not impede the flow in either direction.

Example:

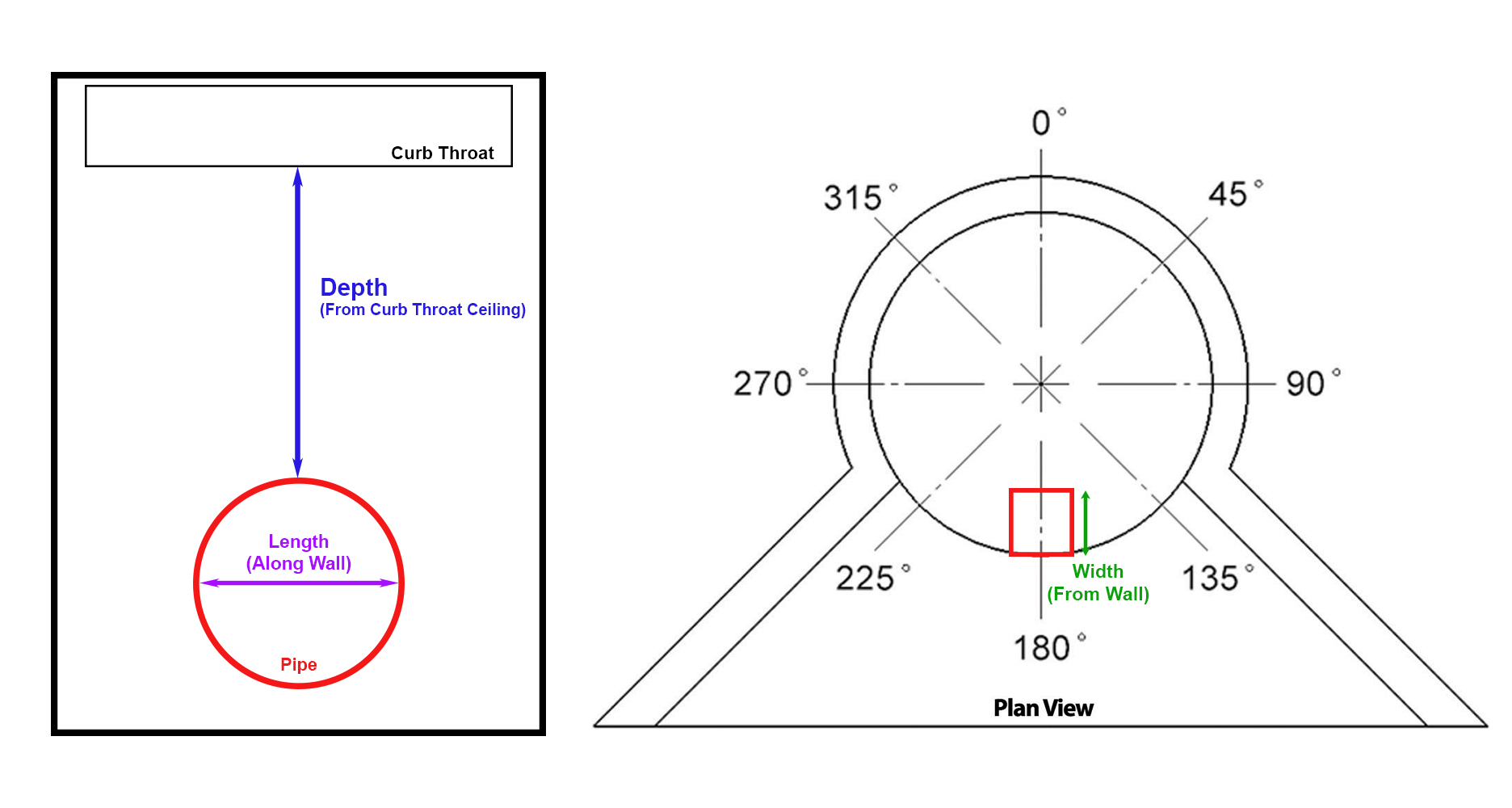

The first thing you’ll do is record the location/angle of the pipe using the plan view as a reference, 0° being the furthest point back from the curb throat and 180° being the point closest to the curb throat. The pipe in this example is centered directly beneath the curb throat, so it is drawn in the plan view at the 180° position.

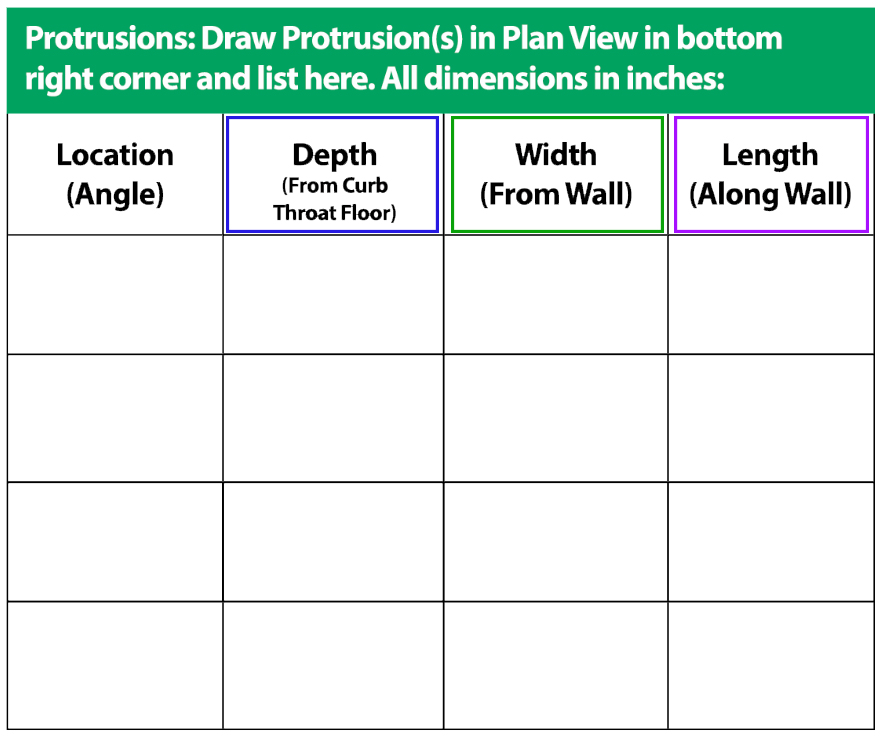

Depth: How far down the pipe is positioned in the inlet. This measurement is made from the floor of the curb throat to the top of the pipe. See the blue arrow in the diagram below.

Width: How far the pipe protrudes out from the interior inlet wall into the clear space. This measurement is made from the interior inlet wall to the end of the pipe. See the green arrow in the plan view below.

Length: How long the pipe is positioned horizontally on the interior inlet wall. This measurement is made from the diameter of the pipe. See the purple arrow in the diagram below.