Solutions With Stormwater Pollution Prevention

Case Study Of PA Company Partnering With Fabco To Provide Stormwater Pollution Prevention

By Warren Cohn

Stormwater pollution prevention is rarely simple—and some end up demanding site-specific innovative solutions, as did the situation Fabco and their partners encountered when they took on the stormwater problems at Dependable Distribution Services, Inc.

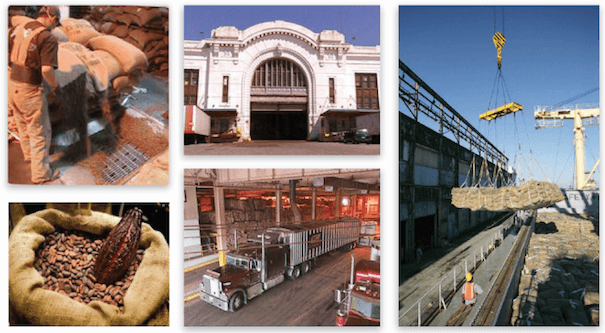

This Philadelphia company is the country’s cocoa bean hub, helping provide the nation with delicious chocolate. Since 1939, Dependable Distribution has been the destination for foreign-grown cocoa beans, as well as a major storage and shipping center. The Philadelphia Water Department’s (PWD) Green City, Clean Waters initiative gave Dependable Distribution the opportunity to retrofit the massive complex to manage its 800,000 gallons of stormwater runoff.

Although the stormwater retrofit was successful and even had the unintended consequence of reducing historic flooding and stormwater pollution on the site, there was an ongoing problem with the permanent post-construction pre-treatment filters inside the existing catch basins. Several different products and vendors were employed to stop the cocoa bean sediment from clogging the stormwater infiltration system, while still allowing for feasible maintenance. None did the job.

Then Dependable Distribution consulted with Emerald Green Infrastructure (EGI). Kate Henry, the president of EGI, studied the stormwater pollution problems there. “The subsurface basins were clogging badly. We were concerned that if they got worse, we wouldn’t even be able to jet the pipes clean. If it got to that, we’d have to rip up the parking lot and take out the entire existing infrastructure.”

Kate Henry has a long history with stormwater pollution and drainage problems. She was already familiar with Fabco’s success in this area. She contacted Fabco’s local distributor—ACF Environmental—and began addressing this complex challenge. Together, ACF, Fabco and EGI surveyed the over 30 stormwater inlets at Dependable Distribution and found a maze of mixed structures and infrastructure that is common in any industrial area around the country.

The team determined that one product solution wouldn’t be able to provide a retrofit solution to the maze of old and varied infrastructure. Instead, the team determined that they needed 13 different stormwater pollution solutions.

PENNSYLVANIA Stormwater BMP Manual

13 different product designs delivered solutions that worked with the old existing urban infrastructure. The result is a stormwater system that saved Dependable Distribution unfathomable financial costs while conforming to mandatory environmental regulations. An added benefit is that the new solutions take a great deal of pressure off the Philadelphia storm sewer system.

Some solutions were as easy as retrofitting existing inlets with standard Fabco Water Quality Inserts (WQIs). Others were more complicated and required customized WQIs specifically designed for individual inlets. For example, a StormSack BMP Round frame filter was merged with a rectangular geotextile bag square frame to fit into the existing infrastructure. In all, 31 different inlets were brought up to modern, strict environmental standards with 13 unique solutions.

To better understand exactly how Fabco, ACF and EGI implemented these ingenious ideas, scroll down to see how the work proceeded. Then think about your stormwater problems. As this example brings to life, Fabco has a solution for every configuration—including yours! See gallery below.

PA Stormwater Reference Material

Stormwater is the water that runs off the land after precipitation, either rain or snowmelt. Rain or snow can drain down into the soil (called infiltration), evaporate back into the atmosphere, be used by plants, or flow into streams or water bodies. The water that runs off the land to streams or lakes is referred to as stormwater runoff. Stormwater runoff happens in natural, undeveloped areas, but typically only for larger storms.

For most areas in Pennsylvania that are wooded or natural meadows, it takes about an inch or more of rain to produce runoff. After development, the natural wooded or meadow areas are replaced with roofs, driveways, sidewalks, and streets. These hard surfaces are called impervious surfaces, and they do not allow water to drain through them, unlike how rain can drain into soil (which is called a pervious surface). When rain falls on impervious surfaces, it runs off rather than infiltrating into the soil or being taken up by vegetation.

Negative impacts of stormwater runoff can include flooding, erosion of streams, sediment build up in lakes, and pollution of streams and lakes. Stormwater flows much faster along a road than it does in the woods. The faster moving water is able to pick up more pollutants like sediment, fertilizers, pesticides, bacteria (from pet waste), and other contaminants, and carry the pollutants to streams and lakes.

An increase in the amount of water that runs off after development and how quickly it runs off can cause erosion and instability in streams. Stormwater runoff can cause streams to become wider, deeper, and straighter, losing their natural bends (or meanders) and decreasing habitat for fish and other animals that live in streams.

Stormwater from developed areas can also be hotter than natural stream sources. Warmer water holds less dissolved oxygen so stormwater can be harmful to fish like trout that need more oxygen. It’s easy to notice the flooding impacts of large rain storms, but over time, smaller storms can have an impact on streams, too. Across the state, about 95% of the rainfall volume occurs in small events (less than 2.4 to 3.2 inches depending on your location.)

Click here to download story as PDF

Click on arrow in gallery below to see all 12 before and after photos