Measuring Stormwater Inlet Protrusions Survey Considerations

Review Information Needed on Inlet Clear Space Protrusions into the Inlet Clear Space and Recording it on the Survey Form

All Fabco Industries Water Quality Inserts (WQIs) are manufactured to properly fit inlets by using specific information compiled in a survey of the “as-built” inlet. The Fabco Grate/Inlet Survey form serves as the tool to provide that information.

Measuring Stormwater Inlet Protrusions

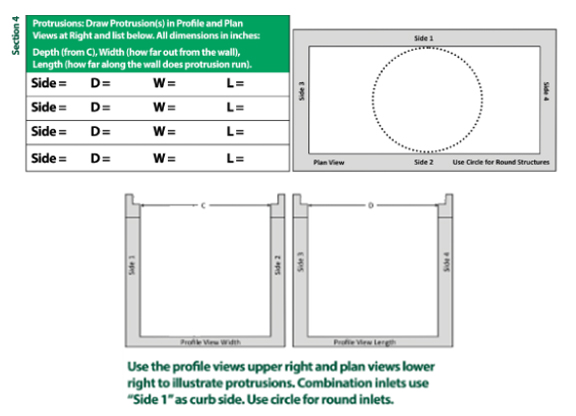

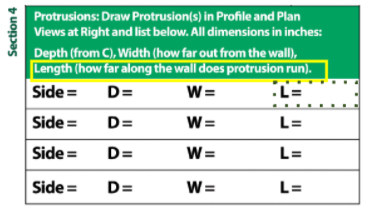

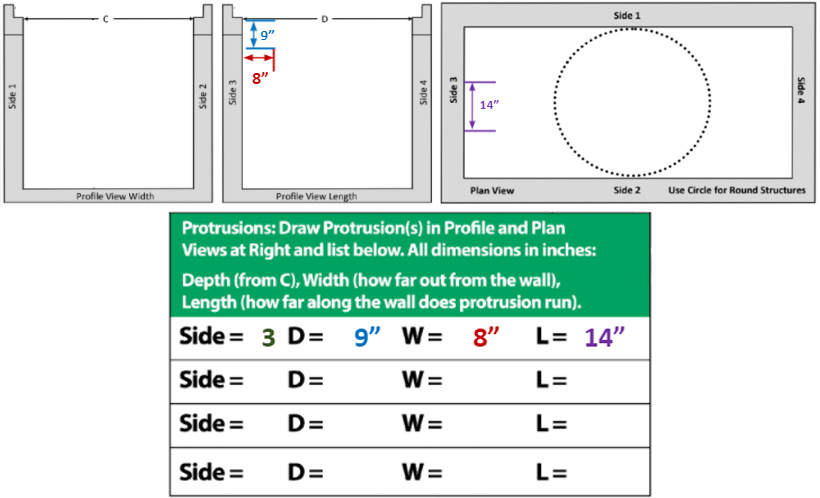

Section 4 of the Grate Inlet Survey Form captures the information relative to anything that protrudes into the inlet clear space. These protrusions can be pipes, concrete ledges, bricks, ladder rungs, etc. Recording these protrusions in the box below while also sketching int he profile and plan view provides Fabco’s engineers with a three-dimensional view of the inlet to design the insert with. Pictures will further enhance the process. Below is a review of exactly what is needed and some examples of how common protrusions should be entered into the available fields.

Side: Enter which side of the inlet the protrusion is on, per the designation on the plan view to the right of this box.

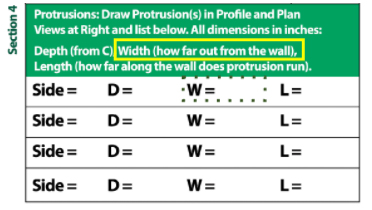

Width: Enter how far the protrusion extends into the clear space. If the wall of the inlet is recessed from the grate frame opening, subtract that distance from the measurement.

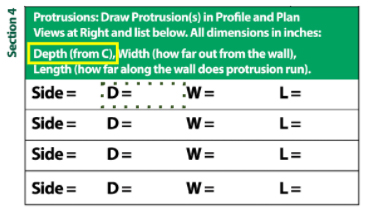

Depth: Enter how far down the top of the protrusion is from the bottom of the grate.

Length: Enter how long the protrusion runs on the inlet wall. A ledge can run the entire length of the inlet wall, a ladder rung or pipe will be a portion of the wall length.

Below are examples of how some common protrusions would be entered in the survey form:

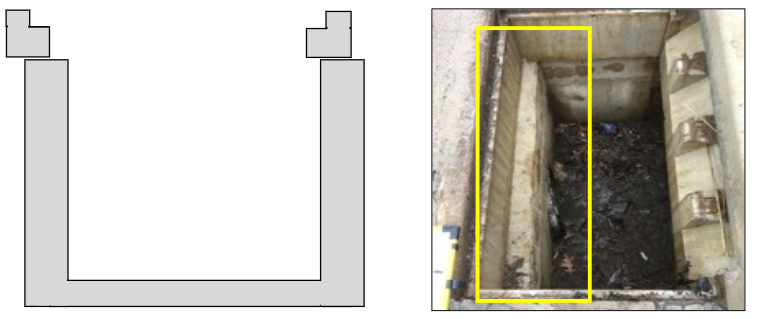

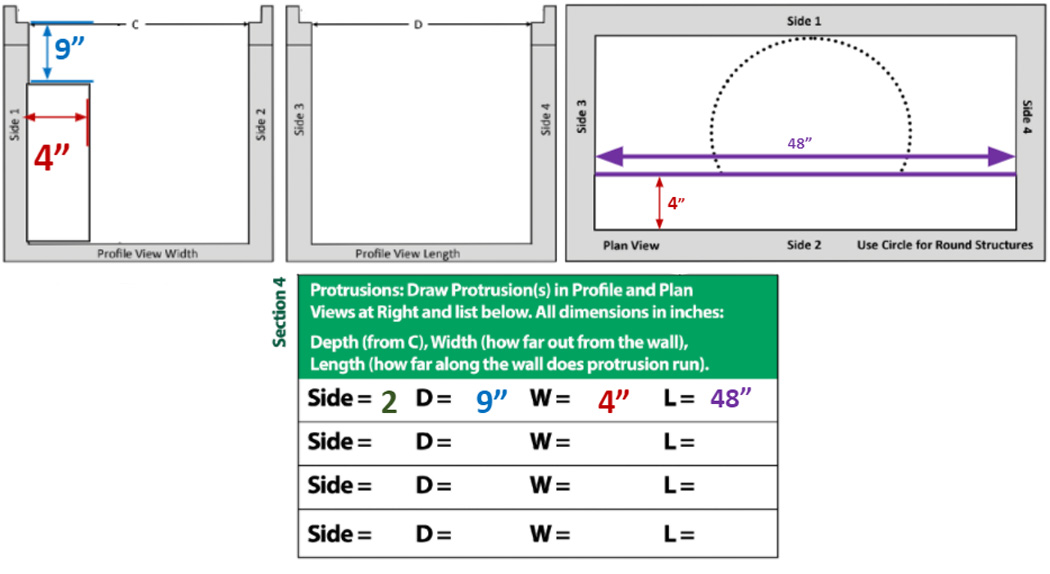

Example 1: Ledge Protrusion

Side:

The concrete ledge protrusion is on side 2 of the inlet.

Depth:

The top of the concrete ledge is 9″ from the bottom of the grate frame lip.

Width:

The concrete ledge protrudes 4″ into the inlet clear space.

Length:

The concrete ledge runs the entire 48″ length of the inlet.

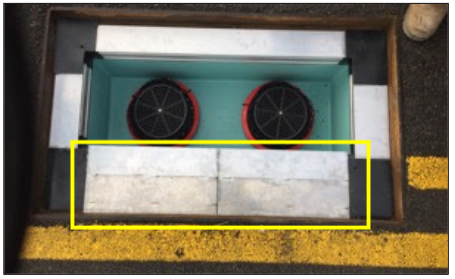

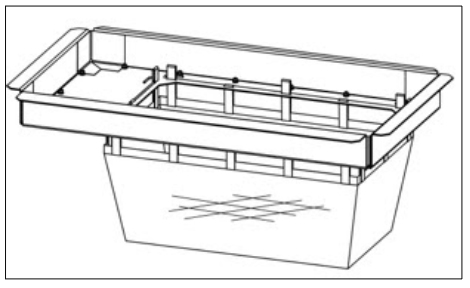

The unit below was designed by Fabco’s engineers to accommodate the ledge protrusion with an extended flange

Example 2: Ladder Rungs

Side:

The ladder rung protrusion is on side 3 of the inlet.

Depth:

The top of the highest ladder rung is 9″ from the bottom of the grate frame lip.

Width:

The ladder rung protrudes 8″ into the inlet clear space.

Length:

The concrete ledge runs 14″ on the 24″ width of the inlet. 48″ length of the inlet.

The unit below was designed by Fabco’s engineers to accommodate the ladder rung protrusion with an extended frame deck.

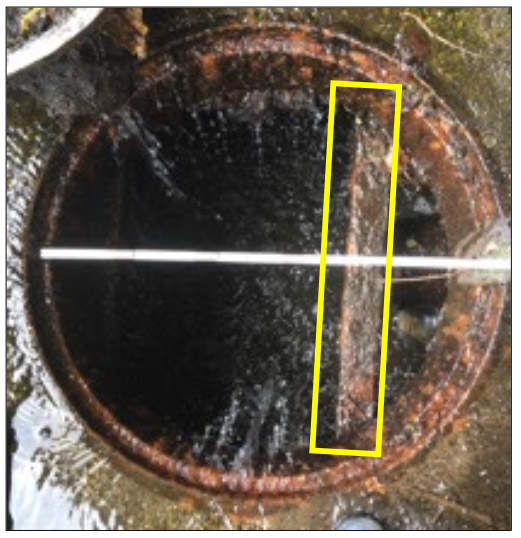

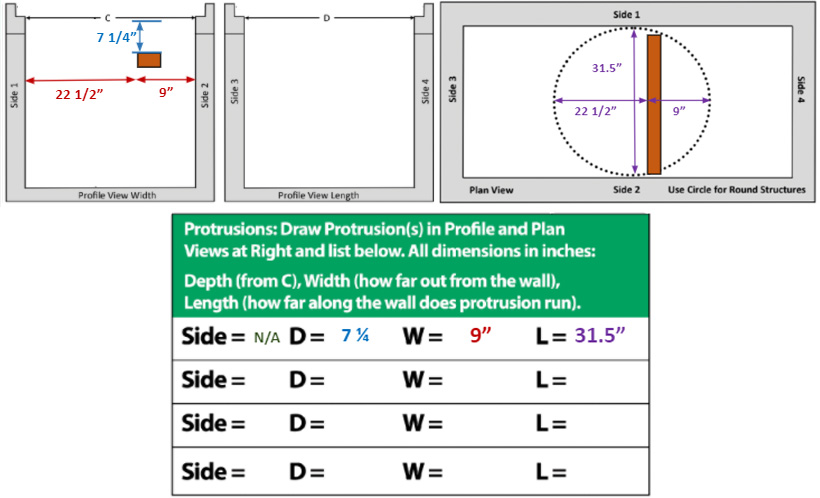

Example 3: Beam In Round Structure

This protrusion is not common, but an example of how to record inlet measurements in general. When working on retrofit applications, there are unlimited variations on existing infrastucture, generally with no as-built drawings so gathering as much information, and as many pictures, as possible will expedite Fabco insert design.

Side:

There are no sides in a round structure, so this field is N/A.

Depth:

The top of the beam is 7 1/4″ from the bottom of the grate frame lip.

Width:

The beam location does not match up exactly with the provided fields. The input provided can be modified to provide as much information as possible. In this example, the edge of the beam on the larger open space is 9″ from the inlet structure.

Length:

The beam does not run the exact diameter of the open space, but the measurement provides insight that the beam runs all the way across the open space.

The unit below was designed by Fabco’s engineers to accommodate the beam protrusion with an extended frame deck.